LQ-670 Service Manual

Rev. A

5-17

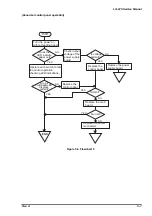

5.5 Repairing the Printer Mechanism

This section provides instruction for repairing the printer mechanism. It describes various problems,

symptom, likely causes, checkpoints, and solutions.

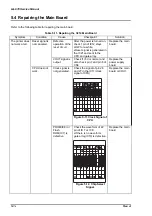

Symptom

Condition

Cause

Checkpoint

Solution

CR motor is

abnormal

CR does not move

even the power is

turned on.

Foreign objects

are attached to

mechanism.

Move the timing belt

manually and check if the

motor rotates or not.

Remove the

foreign objects.

CR motor is

defective

Measure the coil

resistance of the motor.

3.5

Ω±

10%.

(Refer to Table 5-5)

•

If the motor gets short-

circuit, check if the driver

circuit also got short-

circuit.

Replace CR

motor or main

board.

Carriage does

not move even

after the

power is

turned on.

CR motor rotates,

but carriage does

not move.

The pulley drive

is defective.

Check if the pulley is

broken or worn out.

Replace the

pulley drive.

Timing belt is

defective.

Check if the timing belt is

installed on the carriage,

also, the notched part of

the timing belt is worn out

or not.

Replace the

timing belt or re-

install again.

Carriage moves to

left side a little bit,

but stops.

Carriage does

not move

smoothly.

Check if carriage moves

smoothly by hand.

Clean CR guide

shaft and

lubricate it, or

replace the CR

motor.

Carriage stops after

moving to the right

or left edges.

HP sensor is

defective.

---

Replace the HP

sensor.

Printing is

abnormal.

Carriage moves but

no image is printed.

Head FFC is

disconnected or

there is no

continuity.

Check if head FFC is

connected or bent.

Replace the

FFC.

Print head is

defective

Measure head coil

resistance. 39.3

±

2.7

Ω

Replace the print

head(If

necessary

replace the

driver)

The printer does

not print a particular

dot.

Print head is

defective.

Check if the head wire is

broken or not.

Replace the print

head.

Printing result is

uneven or too light.

Print head is

defective

Check if the head wire is

broken or not.

Replace the print

head.

Abnormal

paper feed.

Printing is

performed, but no

paper feed, or

paper feed is not

done smoothly.

Foreign objects

are in the paper

path.

Check the paper path

visually.

Remove the

foreign objects.

PF motor is not

driven correctly.

Check if foreign objects

are attached to the motor

or drive gear, or gears are

damaged or worn out.

Remove the

foreign objects or

replace the

gears.

Table 5-14. Repairing the Printer Mechanism

Summary of Contents for LQ 670 - B/W Dot-matrix Printer

Page 1: ...EPSON IMPACT DOT MATRIX PRINTER EPSON LQ 670 SERVICE MANUAL SEIKO EPSON CORPORATION 4007875 ...

Page 5: ...v REVISION SHEET Revision Issued Data Contents Rev A May 28 1997 First issue ...

Page 114: ...Chapter 6 Maintenance 6 1 Preventive Maintenance 6 1 ...

Page 116: ...LQ 670 Service Manual Rev A 6 2 Figure 6 1 Lubrication Points ...

Page 122: ...LQ 670 Service Manual Rev A A 5 A 2 Circuit Diagram Figure A 2 C214Main Board Circuit Diagram ...

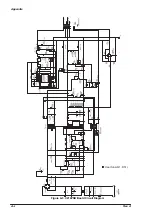

Page 123: ...Appendix Rev A A 6 Heat Sink Q1 D51 Figure A 3 C214PSB Board Circuit Diagram ...

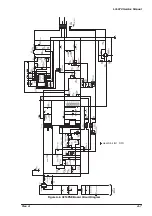

Page 124: ...LQ 670 Service Manual Rev A A 7 Heat Sink Q1 D51 Figure A 4 C214PSE Board Circuit Diagram ...

Page 125: ...Appendix Rev A A 8 A 3 Component Layout Figure A 5 C214 Main Board Component Layout ...

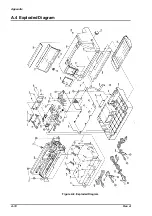

Page 127: ...Appendix Rev A A 10 A 4 Exploded Diagram Figure A 8 Exploded Diagram ...

Page 128: ...LQ 670 Service Manual Rev A A 11 Figure A 9 Exploded Diagram ...

Page 129: ...Appendix Rev A A 12 Figure A 10 Exploded Diagram ...

Page 135: ...EPSON SEIKO EPSON CORPORATION ...