LQ-670 Service Manual

Rev. A

2-3

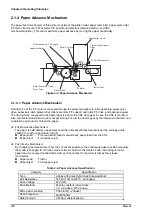

2.1.2 Carriage Mechanism

Carriage Mechanism consists of the carriage movement mechanism and platen gap adjustment

mechanism.

Carriage Movement Mechanism

The figure below shows carriage mechanism. The top of the carriage is supported by the CR guide

frame, and down side is by the CR guide shaft. Since the carriage motor is stepping motor, the

carriage moves freely, and the rotation of the motor is conveyed to the timing belt pulley and drive the

timing belt.

A part of the timing belt is attached to the head carriage, which is moved right and left on the carriage

guide shaft by the rotation of the carriage motor. The timing belt is pre-pressed by the spring and

adjust the elastic motion of the belt which is caused by temperature changes, and keep a certain

belt strength and tension.

The carriage home position detector uses photo coupler method and is located on the right edge of

the mechanism. The detector is detected when the carriage flag interrupts the light emitted from the

photo coupler. The carriage home position control performs open loop control after the HP detector

detects standard position. After the location is determined for the carriage to move by the printing

data, the control circuit calculates the pulse of the motor phase corresponding to the distance to move,

and outputs that information to the motor. Therefore, the detection of mis-location is detected when

the home signal is detected during printing or initialization and the printer goes to the error state.

Also, the moving speed of the carriage is controlled by carriage motor drive frequency according to the

printing data.

Category

Specification

Method

Photoelectric transfer method

Voltage

5VDC

±

5%

Switch Mode

Open

: In the detector range

Close : Out of the detector range

CR Motor

Timing Belt

Carriage

CR Guide Shaft

Spring

Flag

CR Guide Frame

CR Home Position

Detector

Figure 2-2. Carriage Mechanism

Table 2-2. Specification of the Carriage HP Detector

Summary of Contents for LQ 670 - B/W Dot-matrix Printer

Page 1: ...EPSON IMPACT DOT MATRIX PRINTER EPSON LQ 670 SERVICE MANUAL SEIKO EPSON CORPORATION 4007875 ...

Page 5: ...v REVISION SHEET Revision Issued Data Contents Rev A May 28 1997 First issue ...

Page 114: ...Chapter 6 Maintenance 6 1 Preventive Maintenance 6 1 ...

Page 116: ...LQ 670 Service Manual Rev A 6 2 Figure 6 1 Lubrication Points ...

Page 122: ...LQ 670 Service Manual Rev A A 5 A 2 Circuit Diagram Figure A 2 C214Main Board Circuit Diagram ...

Page 123: ...Appendix Rev A A 6 Heat Sink Q1 D51 Figure A 3 C214PSB Board Circuit Diagram ...

Page 124: ...LQ 670 Service Manual Rev A A 7 Heat Sink Q1 D51 Figure A 4 C214PSE Board Circuit Diagram ...

Page 125: ...Appendix Rev A A 8 A 3 Component Layout Figure A 5 C214 Main Board Component Layout ...

Page 127: ...Appendix Rev A A 10 A 4 Exploded Diagram Figure A 8 Exploded Diagram ...

Page 128: ...LQ 670 Service Manual Rev A A 11 Figure A 9 Exploded Diagram ...

Page 129: ...Appendix Rev A A 12 Figure A 10 Exploded Diagram ...

Page 135: ...EPSON SEIKO EPSON CORPORATION ...