Maintenance 6. Arm #2

G3 Rev.14

113

6.1 Replacing Joint #2 Motor

Name

Quantity

Note

Maintenance

Parts

AC Servo Motor (150W)

1

R13B000615

Tools

Hexagonal wrench

width across flats: 2 mm

1

For M4 set screw

width across flats: 3 mm

1

For M4 screw

width across flats: 4 mm

1

For M5 screw

Torque wrench

1

Nippers

1

For cutting wire tie

Wiping cloth

1

For wiping grease

Material

Wire tie

4

Grease

Grease (SK-2)

3 g

Joint #2 motor

Removal

(1) Turn ON the Controller.

(2) Push down the shaft to its lower limit while pressing the brake release switch. Be

sure to keep enough space and prevent the end effector hitting any peripheral

equipment.

The brake release switch affects only Joint #3. When the brake release switch is

pressed, the brake for the Joint #3 is released simultaneously.

Be careful of the shaft while the brake release switch is being pressed because the

shaft may be lowered by the weight of an end effector.

(3) Turn OFF the Controller.

(4) Remove the arm top cover.

For details, refer to

Maintenance: 3.1 Arm Top Cover

.

(5) Remove the battery board.

(6) Remove the user plate.

(7) Cut off the wire tie used for binding the cables connected to the user cable.

(8) Cut off the wire tie used for binding the motor cables to the Joint #2 motor.

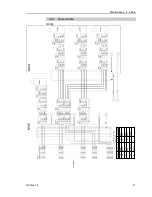

(9) Disconnect the following connectors.

Connectors X221, X21 (Hold the claw to remove.)

Connector X62

(10) Remove the Joint #2 motor unit from Arm #2.

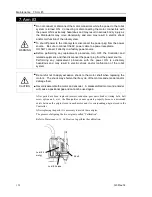

If the motor cannot be removed easily, pull it out

while moving Arm #2 slowly by hand.

Also, the motor flange touches the intermediate

pulley and you cannot pull the motor straight

upward. Therefore, tip the motor and pull it

avoiding he intermediate pulley.

3-M4

×

12

Summary of Contents for G3 Series

Page 1: ...Rev 14 EM183R3623F SCARA ROBOT G3 series MANIPULATOR MANUAL ...

Page 2: ...MANIPULATOR MANUAL G3 series Rev 14 ...

Page 8: ...vi G3 Rev 14 ...

Page 14: ......

Page 84: ...Setup Operation 5 Motion Range 72 G3 Rev 14 ...

Page 86: ...74 ...

Page 200: ...Maintenance 15 Maintenance Parts List 188 G3 Rev 14 ...