Maintenance 7. Arm #3

G3 Rev.14

127

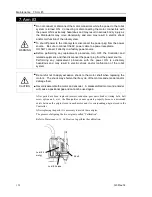

(6) Put the pulley to the U2 belt and place the

Joint #4 motor unit on the Arm #2 surface.

Make sure the motor cables face to the

end of the arm.

3-M4

×

12 + washer

Joint #4

motor unit

3-M4

×

12 + washer

Joint #3

motor unit

Joint #4

intermediate shaft

3-M4

×

12

+ washer

(7) Loosely secure the Joint #4 motor unit to

Arm #2.

Check that the motor unit can be moved

by hand, and it will not tilt when pulled.

If the unit is secured too loose or too tight,

the belt will not have the proper tension.

Joint #4

motor unit

U2 belt

U1 pulley

U1 belt

U2 pulley

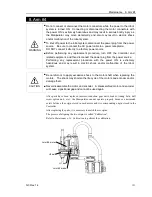

(8) Loosely secure the spline plate to Arm #2.

After moving the shaft up and down several times, secure the spline plate to Arm #2.

(9) Apply the proper tension to the U1 belt, and

then secure the Joint #4 motor unit.

To do so, pass a suitable cord or string

around the Joint #4 motor unit near its

mounting plate. Then, pull the cord using a

force gauge or similar tool to apply the

specified tension shown in the figure on the

right.

3-M4

×

12

+ washer

U1 belt tension = 74 N (7.5

±

0.5 kgf)

Force gauge

Joint #4

motor unit

(10) Apply the proper tension to the Z belt, and

then secure the Joint #3 motor unit.

To do so, pass a suitable cord or string

around the Joint #3 motor unit near its

mounting plate. Then, pull the cord using a

force gauge or similar tool to apply the

specified tension shown in the figure on the

right.

3-M4

×

12 + washer

Z belt tension = 74 N (7.5

±

0.5 kgf)

Force gauge

Joint #3

motor unit

(11) Connect the connectors.

Connectors: X231, X241, X31, X32, X41

Summary of Contents for G3 Series

Page 1: ...Rev 14 EM183R3623F SCARA ROBOT G3 series MANIPULATOR MANUAL ...

Page 2: ...MANIPULATOR MANUAL G3 series Rev 14 ...

Page 8: ...vi G3 Rev 14 ...

Page 14: ......

Page 84: ...Setup Operation 5 Motion Range 72 G3 Rev 14 ...

Page 86: ...74 ...

Page 200: ...Maintenance 15 Maintenance Parts List 188 G3 Rev 14 ...