TB-6594

Page 6 of 12

© 2016 DESCO INDUSTRIES, INC.

Employee Owned

A. Touchscreen Display:

Displays the keypad, time,

date, command prompts, test results and settings.

B. Embedded HID OMNIKEY® Proximity Reader:

Users can begin their test by holding their proximity

badge in front of the proximity reader symbol.

Custom proximity reader interfacing available. Contact

EMIT Customer Service for more information.

C. Single-Wire Wrist Strap Jack:

Connect your

single-wire wrist cord here to test your wrist strap.

See “10mm Wrist Cord Adapter” on page 7 if using

single-wire wrist cords with a 10mm snap termination.

D. Dual-Wire Wrist Strap Jack:

Connect your

dual-wire wrist cord here to test your wrist strap.

E. Steady-State Test Switch:

Place and hold your

finger here to begin the test.

F. CCD Barcode Scanner:

Reads Code 39 and

128 barcode symbologies by default. Other barcode

symbologies are available upon request.

G. Ethernet Jack:

Provides communication to the

SmartLog Pro™ over a network. See “Network Setup”

on page 8 for more information.

H. Foot Plate Jack:

Connect one end of the foot plate

cable here and the other end to the dual foot plate.

I. 5VDC Power Jack:

Connect the included power

adapter here to power the SmartLog Pro™.

J. Dual USB Ports:

Used for EMIT certified external

readers and accessories.

K. Cable Tie Mount:

Use the included zip ties to

secure all cables and cords connected to the SmartLog

Pro™.

L. Power Switch:

Slide the switch to the top position

to turn ON the SmartLog Pro™. Slide the switch to the

bottom position to turn OFF the SmartLog Pro™.

M. Relay Terminal:

Can be integrated with electronic

door locks, lights, buzzers, etc. See “Relay Terminal”

on page 8

for more information.

N. Ground Terminal:

Secure the tinned wire

termination of the included ground cord to this terminal.

Connect the ring terminal termination of the cord to

equipment ground. This connection will remove any

static charge from the user before the test.

NOTE: Failure to correctly ground the SmartLog Pro™

may result in damage not covered under warranty.

O. ESD Glove Test Fixture Port:

Used for connecting

the EMIT 50755 ESD Glove Test Fixture. See

TB-6586

for more information.

Installation

The following procedures will walk you through the

setup and installation of your SmartLog Pro™.

Hardware Setup

If the SmartLog Pro™ is located near a restroom,

sink or other water source, operators will need to be

instructed to thoroughly dry their hands before testing.

Wet hands may cause inaccurate test results and

damage to the tester.

1. Connect the ground cord, foot plate cable, Ethernet

cable and power adapter to the SmartLog Pro™.

2. Route all cables through the U-shaped opening

located at the bottom of the SmartLog Pro and

secure them to the cable tie mount with the included

zip tie.

3. Connect the ground cord’s ring terminal to a known

ground point. Connect the foot plate cable to

the foot plate. Verify that the Ethernet cable is

connected to your network.

4. Connect the power adapter to an appropriate power

outlet, and power the SmartLog Pro™ by sliding its

power switch to the ON position. The display will

turn on, and the boot sequence will intiate. “Scan

or Enter ID” will display on the SmartLog Pro™ after

the boot sequence has completed. The blue LEDs

will continuously cycle around the test switch when

the ESD tester is on standby.

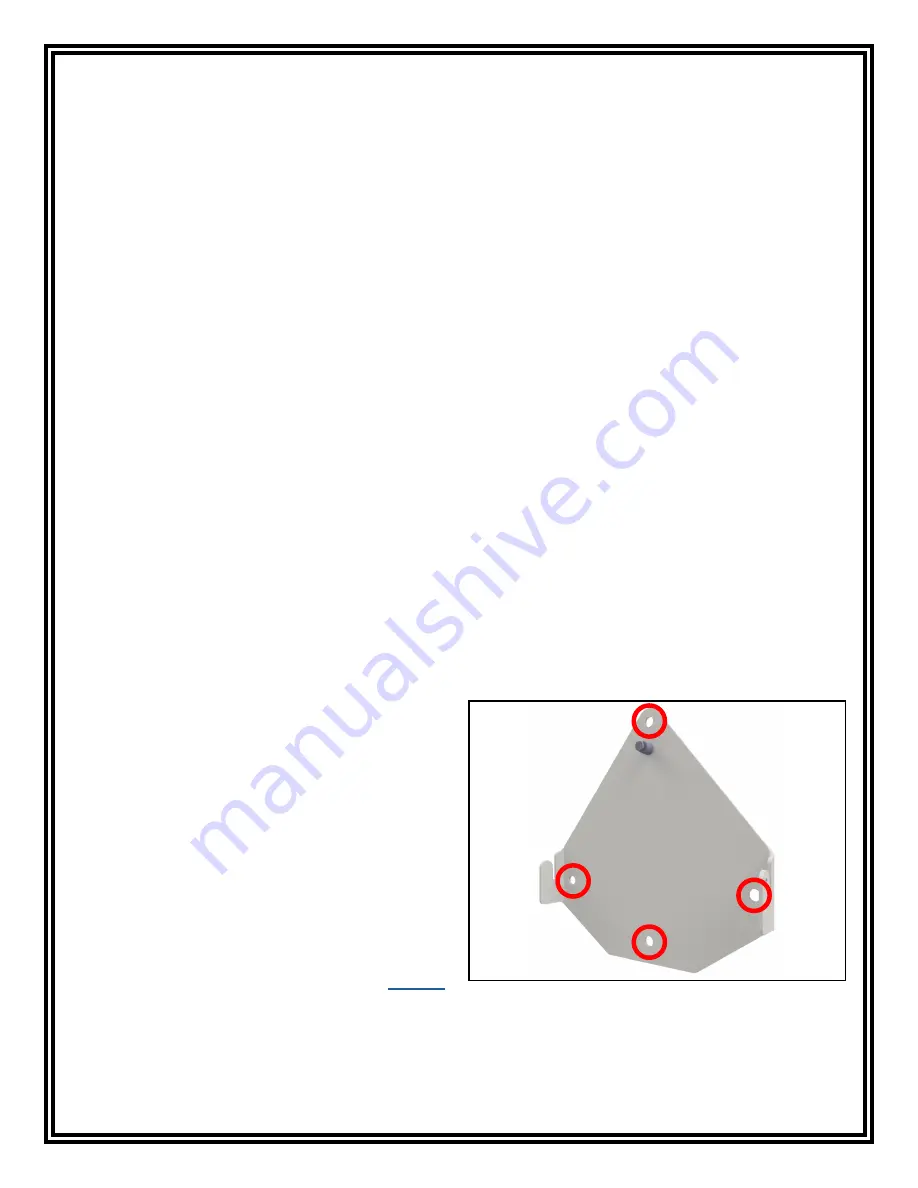

5. Use the included screws and anchors to secure

the mounting bracket to the desired location. The

screws may be used in any of the four holes shown

below. Be sure to locate the bracket where users

can read the display and use the tester.

Figure 4. Mounting holes on the SmartLog Pro™

mounting bracket