TB-6594

Page 9 of 12

© 2016 DESCO INDUSTRIES, INC.

Employee Owned

STATIC IP PROCEDURE

1. Share the MAC address of the SmartLog Pro™

with an IT administrator, so a static IP address

can be assigned to the unit. The MAC address

can be found on a label applied to the back of the

SmartLog Pro™.

2. Use an Ethernet cable to connect the SmartLog

Pro™ to your network. Power the SmartLog Pro.

3. The SmartLog Pro will communicate with the

network server and recieve the static IP address

assigned by the IT administrator. The IP address

can be located within the Admin Menu.

4. To access the Admin Menu, tap 0 then Enter on the

touchscreen keypad.

5. The SmartLog will prompt for the Admin ID. Tap 0

then Enter.

6. The SmartLog will prompt for the Admin PIN. Tap 0

then Enter.

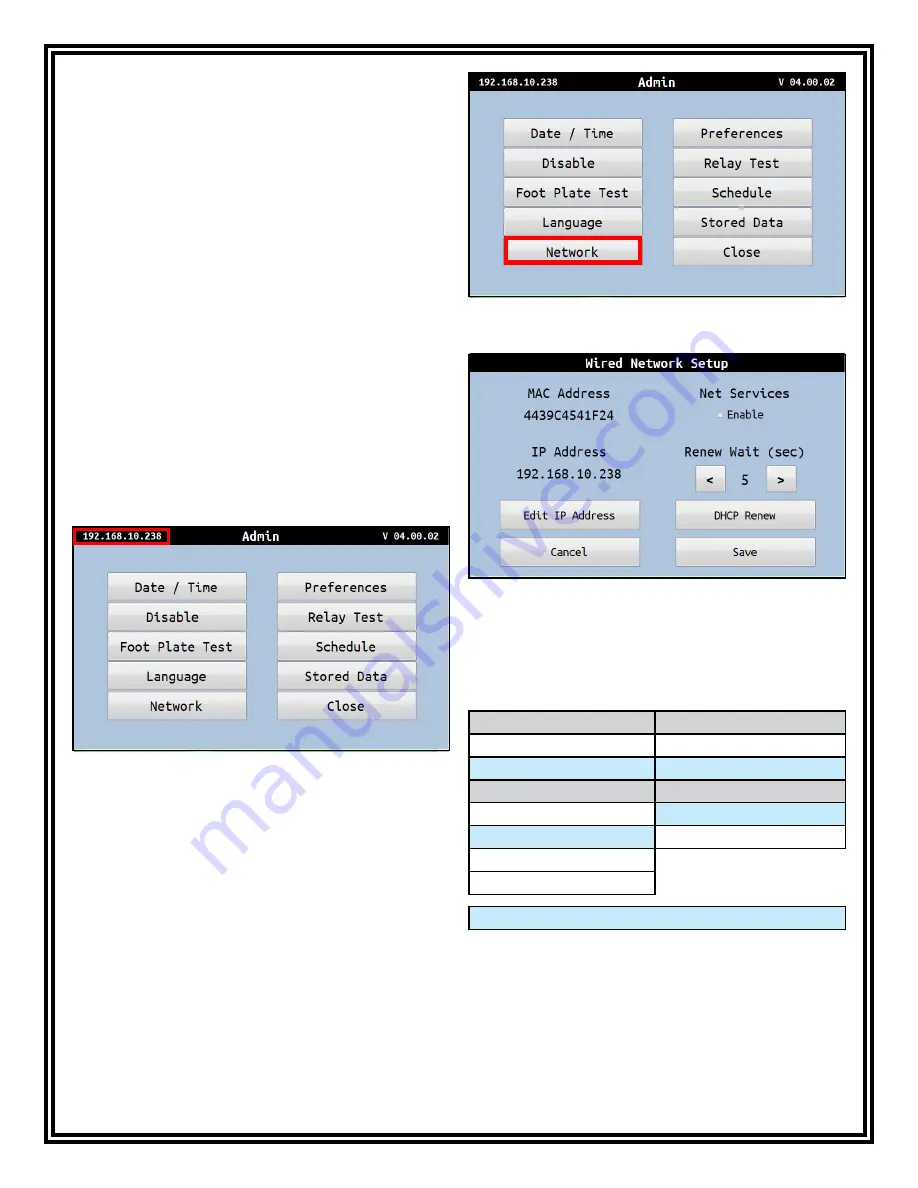

7. The Admin Menu will appear. The IP address

can be found in the top left corner. Take note

of this address as it will be required to establish

communication between the SmartLog Pro and the

TEAM5 Server Software.

Figure 13. Locating the IP address in the Admin Menu

Figure 14. Locating the Newtork button in the Admin

Menu

Figure 15. Wired Network Setup menu

8. Tap the Network button to access the Wired

Newtork Setup Menu. This menu will allow you to

view and edit any network settings if desired.

Test Limit Configuration

The following footwear and wrist strap resistance limits

are available in the SmartLog Pro™:

Footwear

Wrist Strap

LOW Limit Resistance

LOW Limit Resistance

100 Kilohms (1.0 x 10

5

)

100 Kilohms (1.0 x 10

5

)

750 Kilohms (7.5 x 10

5

)

750 Kilohms (7.5 x 10

5

)

HIGH Limit Resistance

HIGH Limit Resistance

10 Megohms (1.0 x 10

7

)

10 Megohms (1.0 x 10

7

)

35 Megohms (3.5 x 10

7

)

35 Megohms (3.5 x 10

7

)

100 Megohms (1.0 x 10

8

)

1 Gigohm (1.0 x 10

9

)**

Default Settings

**A dirty foot plate could result in a false pass when

the footwear limit is set to 1 Gigohm. Be sure to keep

the foot plate clean with 99% isopropyl alcohol when

using this setting. This setting is not suitable for relative

humidity greater than 50%.