2 – 3

VSS/VSR/VSM/VSH/VSSH Compressor • Installation, Operation and Service Manual • Emerson • 35391S

Section 2 • Theory of Operation

needle valve (7), this will allow oil dripping off the co

-

alescing filters to be fed back to the compressor.

This is a continuous cycle.

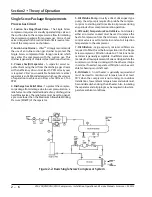

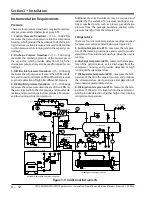

Figure 2-1. Refrigeration Compressor Unit P&ID

(Thermosyphon Oil Cooling with Single Oil Filter Shown)

LG

001

LG

002

FG

001

PI

003

DRAIN

TW

BLEED

MW

BLEED

TW

D100

OIL CHARGE

BLEED

CAPACITY

TW

750W

TW

250#

C100

V100

VOLUME

SUCTION

STOP VALVE

DISCHARGE STOP VALVE

D101

P100

TW

750W

TW

750W

DRAIN

DISCHARGE CHECK VALVE

PI

002

PI

001

TE

001

TE

004

QE

003

TE

005

PI

004

BLEED

PT

004

PT

003

PT

002

D102

D103

TW

TE

002

QE

001

QE

002

OIL SEPARATOR

COALESCING OIL

RETURN LINE

HIGH PRESSURE

R717 VAPOR OUTLET

R717 VAPOR

TO ATMOSPHERE

LOW PRESSURE

R717 VAPOR INLET

PT

001

COMPRESSOR

MOTOR

FIL

TER

MOTOR AND

OIL PUMP

T

E100

R717 LIQUID

INLET

R717 LIQUID/VAPOR

OUTLET

100

PSID

SUCTION

CHECK VALVE

OPTIONAL

(STANDARD FOR BOOSTER &

SWING COMPRESSORS ONLY)

11

10

9

1

2

3

5

4

6

7

12

8