5 – 34

Section 5 • Maintenance/Service

VSS/VSR/VSM/VSH/VSSH Compressor • Installation, Operation and Service Manual • Emerson • 35391S

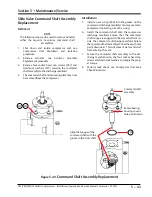

Compressor Shaft Seal Replacement - For

VSS/VSM Units

Tools

Table 5-8. Shaft Seal Tool Kits

Model

(VPN) for the Shaft Seal

Tool Kits

VSM 97 - VSM 127

N/A

VSM 152 - VSM 401

25455A

VSM 501-701

25455B

VSS 291-601

25455B

VSS 751-1301

25455C

VSS 1551-2101

25455D

Removal

1. Remove bolts (281) securing shaft seal housing

(218). to compressor.

NOTE

There will be a small amount of oil drainage as the

shaft seal housing is removed.

2. Insert two of bolts (281) into threaded jacking

holes to assist in removing shaft seal housing (218).

3. Remove mating ring (219C) from compressor shaft.

4. Remove oil seal (230) from shaft seal housing (218).

5. Using a brass drift and hammer, tap out cup as-

sembly (219B) from the back side of shaft seal

housing (218).

6. Remove O-ring (260).

Installation

CAUTION

Care must be taken when handling the cup assembly

and mating ring when installing. See Figure 5-40

for handling seal faces with care. Do not touch the

carbon component of the cup assembly or mirror face

on the mating ring as body oil and sweat will cause

corrosion.

NOTE

On VSS 291 - 601 compressors equipped with an

Anti-rotation pin in the shaft seal housing, when

replacing the cup assembly (219B) the Anti-rotation

pin in the housing must be removed. See Figure

5-42.

Suggestion

A spray bottle filled with clean compressor oil may be

used to lubricate the faces of the seals without touching

the seal.

7. Install a new oil seal (230) in seal housing (218).

8. Clean inside shaft seal housing (218) where cup as-

sembly (219B) meets inside shaft seal housing.

9. If applicable, remove protective plastic from cup

assembly (219B).

DO NOT

wipe or touch carbon

component of cup assembly.

10. If carbon component of cup assembly (219B) needs

cleaning, use alcohol and a lint-free cloth to clean.

11. Apply clean compressor lubricating oil to O-ring on

cup assembly (219B).

12. Using shaft seal tool or similar, install cup assembly

(219B) in shaft seal housing (218). If applicable,

align the hole on the back of the carbon cartridge

with the Anti-rotation pin in the seal housing. See

Figure 5-42.

13. Clean compressor shaft and shaft seal cavity in

compressor housing.

14. Apply clean compressor lubricating oil to mating

ring (219C) seating area on compressor shaft. See

Figure 5-42.

15. Apply clean compressor lubricating oil to inside

area of mating ring (219C).

IMPORTANT

DO NOT

wipe or touch the face of the mating ring

(219C) where face meets the carbon component of

the cup assembly (219B).

Figure 5-41. Compressor Shaft Seal Assembly

281

218

219B

219C

260

219

230

Carbon Component

Mirror Face