Water Comfort System · Operating Manual Electronic Temperature Control Unit ELTC-W

BU-091 - 008TCWE

Page 5 of 10

Firmware V0.5.0

Revision 3

Function Description

Normal Operation

The heating cable output is adjusted by a hybrid relay in a frequency ratio

tuned to seconds (period time 10 min.). The frequency ratio is calculated on

the basis of mathematical models of the actual power loss of the pipe and

the actual power of the tape.

With every new start (also after holiday) the heater is activated for 2 hours to

start legionella protection. Before switching on the relay a soft start always

takes place first to reduce the switching current for the relay (20 sec.).

a) Timer Operation

As long as the parameter "Follow Boiler" is not switched to "1", the ELTC-W

works in the timer mode. That means, depending on weekday and time the

stored program is used. A pre-heating period is implemented (Pre-Pow- er)

to have the set temperature reached when the chosen timer operation

starts.

When the temperature is reached, the controller switches to maintenance

temperature.

The following steps are allotted to the timer program accordingly:

0 Output fixed to 0%.

1 The parameter "Economy Mode" is used as set temperature.

2 The parameter "Holding Temp" is used as set temperature.

3 Legionella Protection

→ fixed target temperature is 60° C.

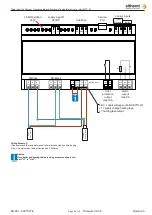

b) Trace Boiler Operation

Is activated by switching parameter "Trace Boiler"on "1". After that the no-

minal value is exclusively determined by the external boiler temperature

sensor. That means, the timer adjustments will be ignored. If this external

sensor measures a temperature higher than the one of parameter "Boiler

Leg. Temp.", the output is set to 100% power to support legionella protection.

If a sensor failure is detected at the boiler temperature sensor, an alarm is

activated and the heating cable output is switched off.

c) Holiday Operation

As soon as for the parameter "Vacation until" a date in the future is entered,

the ELTC-W switches to holiday mode and the power output is deactivated

permanently. When this date is reached (0:00 o'clock) legionella protection

is activated for 2 hours (output set to 100%). After that the timer program is

continued according to the actual date/time.

On the daily date switch (23:59 -> 0:00) the output is operated for a deter-

mined time of 2 hours for legionella bacteria reduction with 100% power. On

the display the remaining time (round up number of days) with a maximum

of 99 days is shown (which means, if the remaining time is under 24 hours

the display shows 1 day).

Frost Protection

By setting the parameter "Activate A.F." the frost protection function is activa-

ted. By a separate sensor input the actual temperature is compared with

the value of the parameter "Switch-On". As soon as the value is reached (or

un- der-run) the output is activated to run the heating tape. As soon as the

value "Switch-On" + "Hysteresis" is exceeded, the output is switched off.

To avoid fast switching cycles a minimum standstill period of 60 seconds is

implemented (that means, after each switch-off of the relay, the re-switch-on

is blocked for 60 seconds). If a sensor failure occurs, the alarm relay is set

and the output is (permanently) switched-off.

Maximum Operation

If level 3 within the timer programming is chosen, the target temperature of

60° C is assumed. When the temperature is reached, the controller switches

to cyclic operation to maintain the temperature.

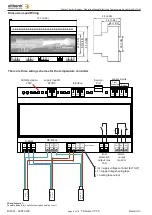

Operation Types (Modes)

Standard Mode

....................... The heating power is regulated to reach

the set maintenance temperature

Eco-Mode

............................... The heating power is regulated to reach

the set power saving temperature

Standby mode

............................... The heating power is shut down to 0

Pmax Mode

..........................The heating power is regulated to maintain

60°C for legionella bacteria prevention

Pre-Heating-Up

........................... The calculated time until reaching the

next desired value level

Trace Boiler Function

................The timer mode is deactivated and the

boiler temperature is used as desired value

Holiday Mode

..... allows to choose a deactivation period for the heating

Failure / Status Reports

no heating tape ............................ no heating tape found or load current less

than 0.2A; Heating tape

possibly too short (<6m),

not connected, line

interruption or defective

no time ......................................................................no timer settings made,

possibly the controller was switched off for longer time,

over temperature .............................................. inner case temperature >60°

relay defect .............................................. short-circuit of heating tape output

internal failure .......................................restart controller, if failure still occurs

contact eltherm GmbH

F.P.Sensor................frost protection sensor defect / breakage / short-circuit

Boiler ...................................... boiler sensor defect / breakage / short-circuit

>Holiday ..........................Controller is in holiday mode for xx days (xx days)