Water Comfort System · Operating Manual Electronic Temperature Control Unit ELTC-W

Page 6 of 10

Firmware V0.5.0

Revision 3

BU-091 - 008TCWE

Parameterliste

1) Grundeinstellungen

Werkseinstellung .............

Sprachauswahl ................

...................................

Datum ...............................

...................................

...................................

Zeit ...................................

...................................

...................................

2) Setup

Haltetemperatur................

...................................

...................................

Spartemperatur.................

...................................

...................................

...................................

Typ Heizband....................

...................................

Umgebungs Temp. ...........

Rohr Durchmesser ...........

Rohr Isolierung .................

Korrekturfaktor..................

...................................

3) Timer

Folge Boiler ......................

...................................

...................................

Boiler Leg.Temp................

...................................

Urlaub bis .........................

...................................

...................................

...................................

Timer ................................

Mo ...................................

Di

...................................

Mi ...................................

Do..................................

Fr...................................

Sa...................................

So...................................

4) Frostschutz

Aktiviere F.S......................

...................................

Einschaltpunkt ..................

Hysterese .........................

...................................

5) Information

Build / Version...................

Temp. Boiler......................

Temp. Frostschutz ............

Temp. Intern G..................

Temp Intern A ...................

Ip Heizband ......................

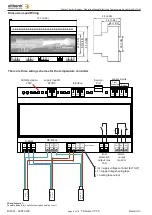

Parameter Listing

1) Base Settings

..(Default Settings)........

..Language Select ........

......................................

..Date Settings ..............

......................................

......................................

..Time Settings..............

......................................

......................................

2) Setup

..Maint. Temp. ...............

......................................

......................................

..Economy Mode ..........

......................................

......................................

......................................

..Tape Type ...................

......................................

..Ambient Temp.............

..Pipe Diameter.............

..Pipe Insulation ............

..Correct. factor.............

......................................

3) Timers

..Trace Boiler ................

......................................

......................................

..Boiler Leg.Temp. ........

......................................

..Vacation until ..............

......................................

......................................

......................................

......................................

..Mo ...............................

..Tu ................................

..We ...............................

..Th ...............................

..Fr..................................

..Sa.................................

..Su.................................

4) Frost Protection

..Activate A.F.................

......................................

..Switch-On ...................

..Hysteresis...................

......................................

5) Info

..Build / Version ............

..Temp. Boiler ...............

..Temp. Antifreeze.........

..Temp Internal G ..........

..Temp Internal A...........

..Ip Heating Tape .........

Description

factory settings (set on 3 and confirm) ...............................

language shown in display .................................................

............................................................................................

Date setting of internal clock. Current date; The ELTC-W

automatically recognizes daylight saving time

according to set date (Display "W" or"S") ..........................

Time setting of internal clock. Current time; The ELTC-W

automatically recognizes daylight saving time

according to set date (Display "W" or"S") ..........................

standard desired value

The ELTC-W will maintain this temperature, if timer

program is set to "2"........................................................

standard desired value → the upper limit depends on

the set temperature for Maint Temp.

The ELTC-W will maintain this temperature, if timer

program is set to "1"........................................................

Select the heating tape. Selection between ......................

ELSR-W-55 and ELSR-W-65.............................................

The minimum expected temperature at pipe location ........

The diameter of water pipe ................................................

The thickness of insulation.................................................

Can be used to adjust the internally calculated power

output to local conditions ...................................................

If the Trace Boiler function is activated, the ELTC-W ........

will follow the temperature of the boiler. Therefore

a temperature sensor is needed at boiler surface..............

If boiler probe detects this temperature or above

legionella protection is activated .......................................

Range

..1-3

..0 = English, ......

..1 = German

..dd.mm.yyyy

..hh:mm:ss

..37°...68°C .........

..37°...68°C .........

..ELSR-W 65 ......

..ELSR-W 55

..0...25°C ............

..15...100mm ......

.. 9...100mm ......

..50...150% .........

............................

..0...1 ..................

..50°...60°C .........

Factory Settings

....0

....45°C

....40°C

....ELSR-W 65

....10°C

....15mm

....9mm

....100%

....

....0

....50°C

As soon as for the parameter "Vacation until" a date in the future is entered, the ELTC-W

switches to holiday mode and the power output is deactivated permanently. When this date is

reached (0:00 o'clock) legionella protection is activated for 2 hours (output set to 100%).

After that the timer program is continued according to the actual date/time.

The ELTC-W has different preset working modes. This.....

working modes describe the behavior of the heater.

0= no heating

1 = Economy Mode

2 = Maint Temp. .................................................................

3 = Legionella Protection ...................................................

You also have the opportunity to set an individual ............

program for each day ......................................................

............................................................................................

............................................................................................

............................................................................................

............................................................................................

............................................................................................

To activate frost protection function switch to "1"

To use frost protection a temperature sensor is needed....

The ELTC-W will maintain this temperature.......................

Hysteresis prevents rapid switching on and off as the

temperature drifts around the set point. .............................

Version and Software Version of device

actual measured boiler temperature

actual measured frost protection temperature

actual measured inner-case temperature No.1

actual measured inner-case temperature No.2

actual measured peak current of heating tape

..Home

Apartment Hou

Restaurant

Hotel

..constant temp.

..individual

..Monday

..Tuesday

..Wednesday

..Thursday

..Friday

..Saturday

..Sunday

..0...1 (on) ...........

..-10...+30°C .......

..1...10K ..............

se

....0 (off)

....2°C

....1K

Parameter Listing