Water Comfort System · Operating Manual Electronic Temperature Control Unit ELTC-W

Page 2 of 10

Firmware V0.5.0

Revision 3

BU-091 - 008TCWE

Circulation Pipe

Electrical Heat Tracing

Warm water circulation system

This system consists of the warm water boiler, warm water pipe,

pump, valves, fittings, and a circulation pipe that is used for

temperature maintenance. The pipes are soldered or pressed

together using fittings.

A circulation pipe does not provide warm water all the way to

the water outlet. A waste of water takes place because the user

must wait until the cold water has left the pipe before the warm

water comes out.

A circulation pipe requires more room for installation,

it is more expensive to install (e.g. cutting the pipe to length,

soldering of fittings, more time = paying installers, etc) and

requires maintenance (e.g. Valve or its seal, and the pump

need replacement)

The operation of a circulation system requires more ener-

gy. (Increased surface and hence increased heat loss due

to double piping; power for pump.)

Warm water electrical heat tracing system

This system uses the same principle as the warm water cir-

culation system but does not require a circulation pipe, pump,

valves and fittings associated with the circulation pipe. Instead

a self-regulating heating cable is used for temperature mainte-

nance.

With electrical heat tracing warm water is provided all the way

to the water outlet. This saves water because the warm water is

readily available when opening the faucet.

This system requires less room because the heating cable is

placed directly on the warm water pipe. So it is less expensive

to install. It does not require maintenance.

With electrical heat tracing you can save up to 65 % of your

energy costs compared to a circulation system.*

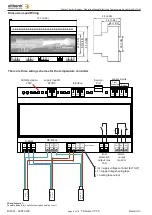

Water Comfort System

2

5

1

Insulation (by Customer)

2

Water pipe (by Customer)

3

EL-Clic T-splice

4

Self-regulating heating cable ELSR-W

5

Self-adhesive aluminum foil

1

6

EL-Clic fast connector system

7

Water boiler (by Customer)

8

Controller

3

4

6

8

* Exemplary system: 1/2 " piping, heated length 10m, 15 mm thermal insulation,

7

power consumption of pump 75 W, maintain temperature 45°C, ambient tempera-

ture 15°C.