Water Comfort System · Operating Manual Electronic Temperature Control Unit ELTC-W

Page 4 of 10

Firmware V0.5.0

Revision 3

BU-091 - 008TCWE

Technical Data

General Connection and Safety Instructions

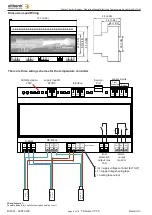

Operating voltage range Input A ....................................100...253VAC, 50Hz

Operating voltage range Input B ...............................................24VDC, ± 5%

Max. power input .....................................<= 6,5VA (@ 253VAC, worst case)

Standby power input................................................... <= 3,5VA (@ 230VAC)

Operating temperature range........................................................-10...+40°C

Storage temperature range...........................................................-20...+65°C

Admissible humidity............................................... 80% RH, non-condensing

Relay outputs

Heating tape maximum current ......................20A (res., max. 250VAC)

Heating Tape while Softstart .................................................... max. 50A

Frost protection-Output maximum current .....16A (res., max. 250VAC)

Alarm-Output maximum current .......................2A (res., max. 250VAC)

requiered minimum current .....................................10mA / 5VDC

Fuse protection .....................................internal 2A, non-changeable cut-out

Advice

This manual has to be accessible to users at any time. We

cannot accept liability for damages caused by unintended

usage or by non-observance of the manual and the safety

instructions! In these cases all warranty claims are void.

This manual contains additional safety instructions within the

product description. Please observe!

If you detect damage, the product should NOT be connected

to voltage!

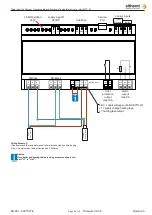

Current control…………………………………………………….limit 0,2 A

“error” corresponds 6 m heating cable in nominal rating

Inputs ........................................................2x NTC-Temperature sensors

Measuring-/Display range ................................................... max. -20...+60°C

Resolution .................................................................................................0,1K

Accuracy .................................................................................. ±1K, ±1 Digit

Display ..........................................................................LCD, 128x32 Pixel

Adjustment range ............................................................. see parameter lists

Interface

.......................... RS 485, half duplex, 8N1, max 38,4 kBaud

Communication protocol ....................................................................... E-Link

Data preservation ..............................................................................unlimited

Clock

.........................................Quartz, automatic daylight saving time.

Runtime without line voltage ....................................................... typ. 10 days

Housing ................................................................... Plastic with foil buttons

for standard busbar 35mm, IP 20

Danger

It presents a danger to life!

A safe operation might not be possible if:

• the device has visible damage,

• the device does not work,

• after longer storage in inappropriate conditions.

• contamination or humidity.

• after hard transport stress.

•

Installation and operation of the device must be

carried out by a certified electrician or under

observation by a certified electrician.

• Keep the device safely disconnected from voltage

while mounting. Danger of electric shock!

• Never operate the device without housing.

Danger of electric shock!

• An existing PE-terminal of the device must be put on

PE! Danger of electric shock!

Additionally

the internal filtering of errors would only function

partly, so deficient displays can be the result.

• The device must only be used for the purpose

described in this document.

• Please observe the required safety regulations and

standards in the place of installation.

• Before usage of the controller please check its operating

conditions (see technical data), e.g.:

Caution

Advice

- Power supply (printed on the device)

- Required ambient conditions

(temperature or humidity limits)

- Maximum stress to the relay contacts in relation with

the maximum starting currents of the users (e.g.

engines, heaters).

In case of non-observance malfunctions or damages

are possible.

• Observe when extending sensor cables: The cross

section is uncritical but should be 0,5mm² minimum.

Thinner cables can cause error displays.

• Avoid installation directly next to big contactors (strong

interferences are possible).

• Please observe the necessary requirements when

installing data lines.

Cleaning

Do not use acid or acidic means to clean the front

foil. Danger of damage!

We declare that the described product is in full compliance with

the directives 2006/95/EC, 2004/108/EC and 2011/65/EU. If you

RoHS

need a detailed declaration of conformity, please contact us.