en

Angle sensors

Date: 09.06.2020

9010020A00M - V01

19/20

f

Ensure the connections are not strained.

f

Connect the angle sensor in accordance with

the wire colours/connector pin assignments in

the data sheet.

f

Route the cable so that no damage can arise

(e.g. due to kinks, breaks, rubbing points).

Pleas take strain relief under consideration.

f

Route wires so that they are rigidly fixed if they

will be exposed to temperatures less than -5°C.

f

After installing, hand over the installation man-

ual to the end-user.

6.3 Putting into service

f

Ensure that the electrical specifications are ad-

hered to. The values must never be exceeded!

f

Do not apply or remove electrical connection

when under voltage.

f

Install entire system or the vehicle in an

EMC-compliant manner. The installation

environment influences the EMC of the angle

sensor. Install the angular sensor and route the

supply lines in a spatially separated manner or

at a great distance to lines with a high interfer-

ence levels (frequency converters, contactors,

etc.).

f

Connect the power and check operation of the

angle sensor.

f

Non-assigned outputs must no be connected.

9

The angle sensor is ready for operation.

Function check

NOTICE

Danger due to processes starting

inadvertently

f

During the function check during

use, be aware of other processes

starting inadvertently!

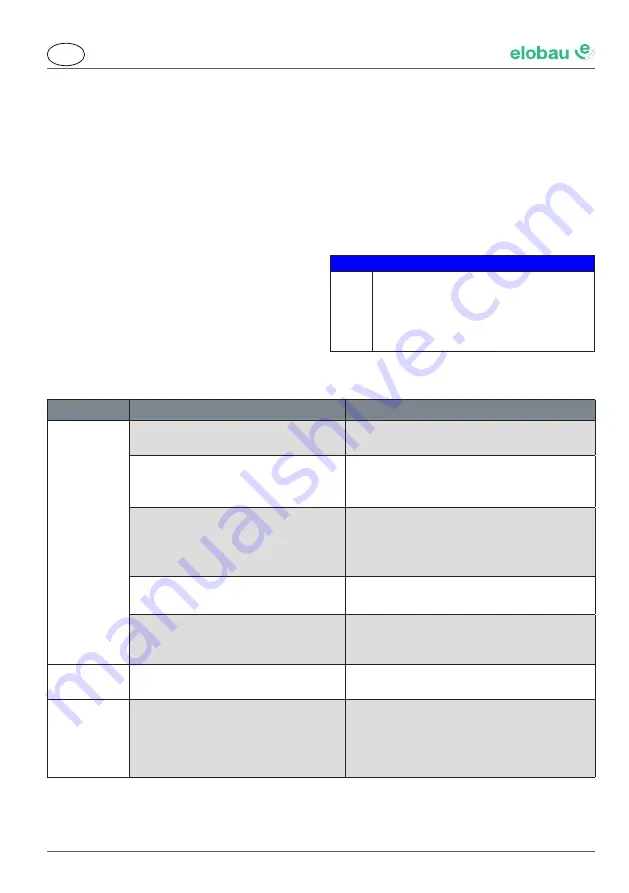

6.4 Faults/troubleshooting

Problem

Cause

Remedy

No or incor-

rect Signal

Angle sensor not correctly connected

due to plug connection assignment

f

Adhere to the data sheet for plug connec-

tion assignment.

External magnetic field

f

Angle sensor shielding

f

Remove/supress the external magnetic

field

Hall sensor defective

Demagnetisation of permanent

magnets

f

Replace the sensor / return it to the

factory

Connected cable defective due to

incorrect attachment

f

Cable replacement

f

Route the cable correctly

Zero-point position of the drive shaft

does not correspond to the actual

zero-point position.

f

Take the zero-point position of the drive

shaft under consideration

Damage of

housing

External mechanical or chemical

impact on the sensor

f

Replace the sensor.

Bearing

clearance

/ blockage

of the drive

shaft

Mechanical overload

f

Replace the sensor.

f

Contact elobau.

f

Please adhere to permissible mechanical

stress of the drive shaft.