viii - combustion air and vent pipe

While cement is still wet, insert pipe into socket with a ¼ turn

8.

twist. Be sure pipe is fully inserted into fitting socket.

Wipe excess cement from joint. A continuous bead of cement

9.

will be visible around perimeter of a properly made joint.

Handle pipe joint carefully until cement sets.

10.

Support combustion air and vent piping a minimum of every

11.

5’

using pre-formed metal hanging straps. Support combustion

air and vent piping so no weight is resting on the boiler jacket.

Do not rigidly support pipes. Allow movement due to expan-

sion and contraction.

Slope combustion air and vent pipes toward boiler a mini-

12.

mum of ¼” per linear foot with no sags between hangers.

Use appropriate methods to seal openings where vent and

13.

combustion air pipes pass through roof or side wall.

NOTICE

NOTE: It is recommended that all pipes be cut, prepared,

and pre-assembled before permanently cementing any

joint.

After pipes have been cut and pre-assembled, apply cement

7.

primer to pipe fitting socket and end of pipe to insertion mark.

Quickly apply approved cement to end of pipe and fitting

socket (over primer). Apply cement in light, uniform coat on

the inside of socket to prevent buildup of excess cement. Apply

second coat.

NOTICE

NOTE: Primer and cement will discolor jacket. Take pre-

cautions to protect jacket while cementing vent pipe.

iX - Gas supply pipinG

check Gas supply

The gas pipe to your boiler must be the correct size for the length of

run and for the total BTU per hour input of all gas utilization equip-

ment connected to it. See Table 4 for proper size. Be sure your gas

line complies with local codes and gas company requirements.

The boiler and its individual shutoff valve must be disconnected

from the gas supply piping system during any pressure testing of that

system at test pressures in excess of ½ psig (3.5kPa).

The boiler must be isolated from the gas supply piping system by

closing its individual manual shutoff valve during any pressure

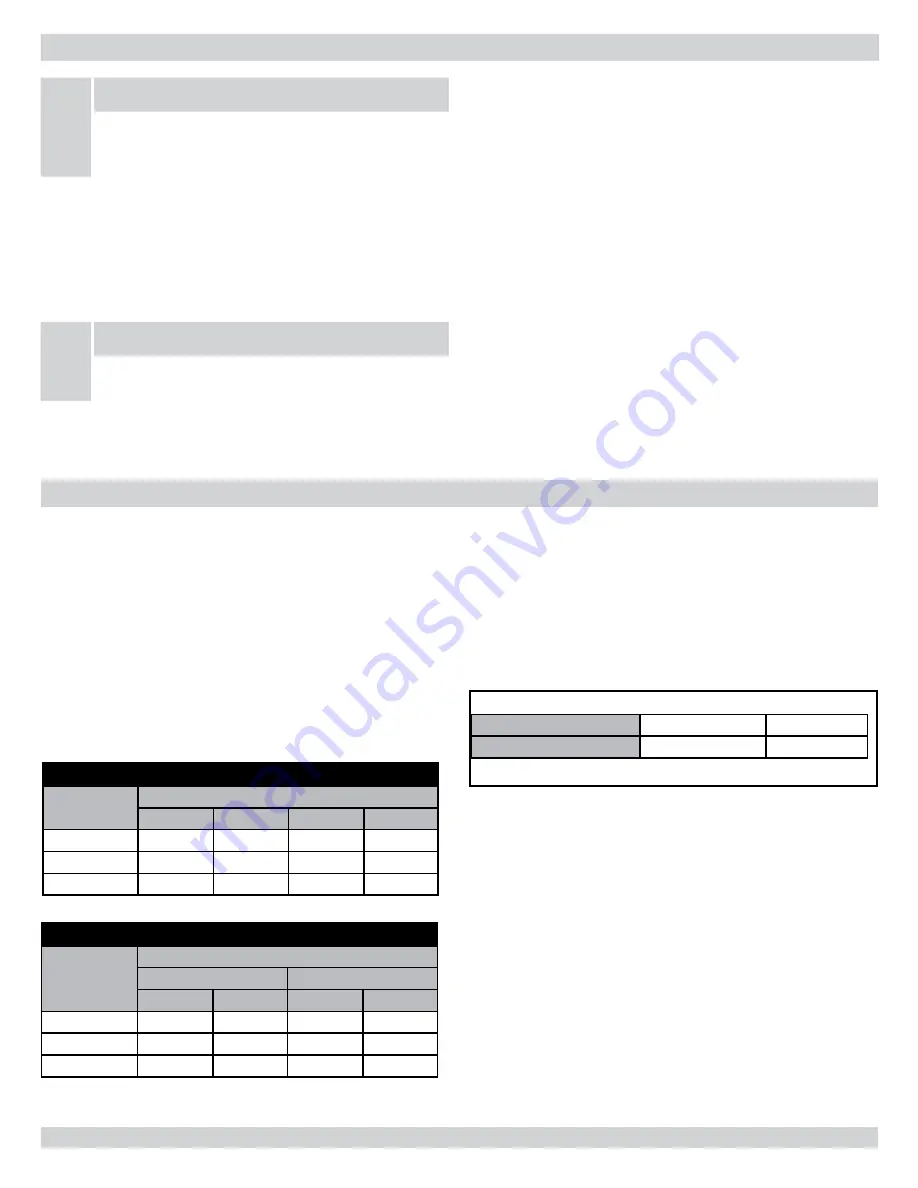

taBLE 5: GaS SUPPLY PRESSURE

Natural Gas

4” min. w.c.

10” max. w.c.

LP Gas

10” min. w.c.

14” max. w.c.

Check line pressure while unit is running in high fire mode.

taBLE 4: GaS PiPiNG SiZES

Natural Gas

Pipe Length

Pipe capacity - BtU/Hr. input includes Fittings

½”

¾”

1”

1¼”

20’

92,000

190,000

350,000

625,000

40’

63,000

130,000

245,000

445,000

60’

50,000

105,000

195,000

365,000

LP Gas

Pipe Length

Pipe capacity - BtU/Hr. input includes Fittings

copper tubing (O.D.)

iron Pipe

⅝”

¾”

½”

¾”

20’

131,000

216,000

189,000

393,000

40’

90,000

145,000

129,000

267,000

60’

72,000

121,000

103,000

217,000

The length of pipe or tubing should be measured from the gas meter or

propane second stage regulator.

connecting the Gas piping

Refer to

Figure 9

for the general layout at the boiler, which

shows the basic fittings you will need. As shipped, the gas line

enters the boiler through the right side but, as an option, it can

be routed through either the rear or left side panel.

testing of the gas supply piping system at test pressures equal to or

greater than ½ psig (3.5kPa).

In order for proper operation of the boiler, it is recommended that

the line pressure be within the minimum and maximum values in

Table 5

.

14

Summary of Contents for UTICA BOILERS UB95M-200

Page 26: ...26 ...

Page 45: ...45 ...

Page 46: ...46 ...

Page 47: ...NOTES ...

Page 48: ...Date Service Performed Company Name Tech Initials Company Address Phone ...