v - before installinG the boiler

The clearances shown in

4.

Table 3

indicate required clearances

per CSA listing. A minimum 1” clearance must be maintained

between combustible construction and each of the right, top

and back surfaces of the boiler. Allow at least 24” at the front

and left side and 8”at the top for servicing. No combustible

clearances are required to venting or combustion air intake

piping.

taBLE 3: BOiLER cLEaRaNcES*

Dimension

combustible

construction

accessibility/

cleaning

Service

Top

1”

8”

8”

Left Side

1”

24”

24”

Right Side

1”

-

-

Base

1”

-

-

Front

0

24”

24”

Back

6”

-

-

Intake/Vent Piping

0

-

-

Near Boiler Hot

Water Piping

1”

-

-

* All distances measured from the cabinet of the boiler.

Equipment shall be installed in a location which facilitates the

5.

operation of venting and combustion air intake piping systems

as described in this manual.

Advise owner of boiler to keep venting and combustion air

6.

intake passages free of obstructions. Both the venting and com-

bustion air intake piping systems connected to the outdoors

must permit flow through the piping systems without restric-

tions for the boiler to operate.

The boiler shall be installed such that the automatic gas ignition

7.

system components are protected from water (dripping, spray-

ing, rain, etc.) during operation and service (circulator replace-

ment, control replacement, etc.).

The boiler must be located where ambient room temperatures

8.

(minimum possible temperatures where boiler is installed as-

suming boiler is not in operation and therefore contributes no

heat to the space) are always at or above 32°F to prevent freez-

ing of liquid condensate.

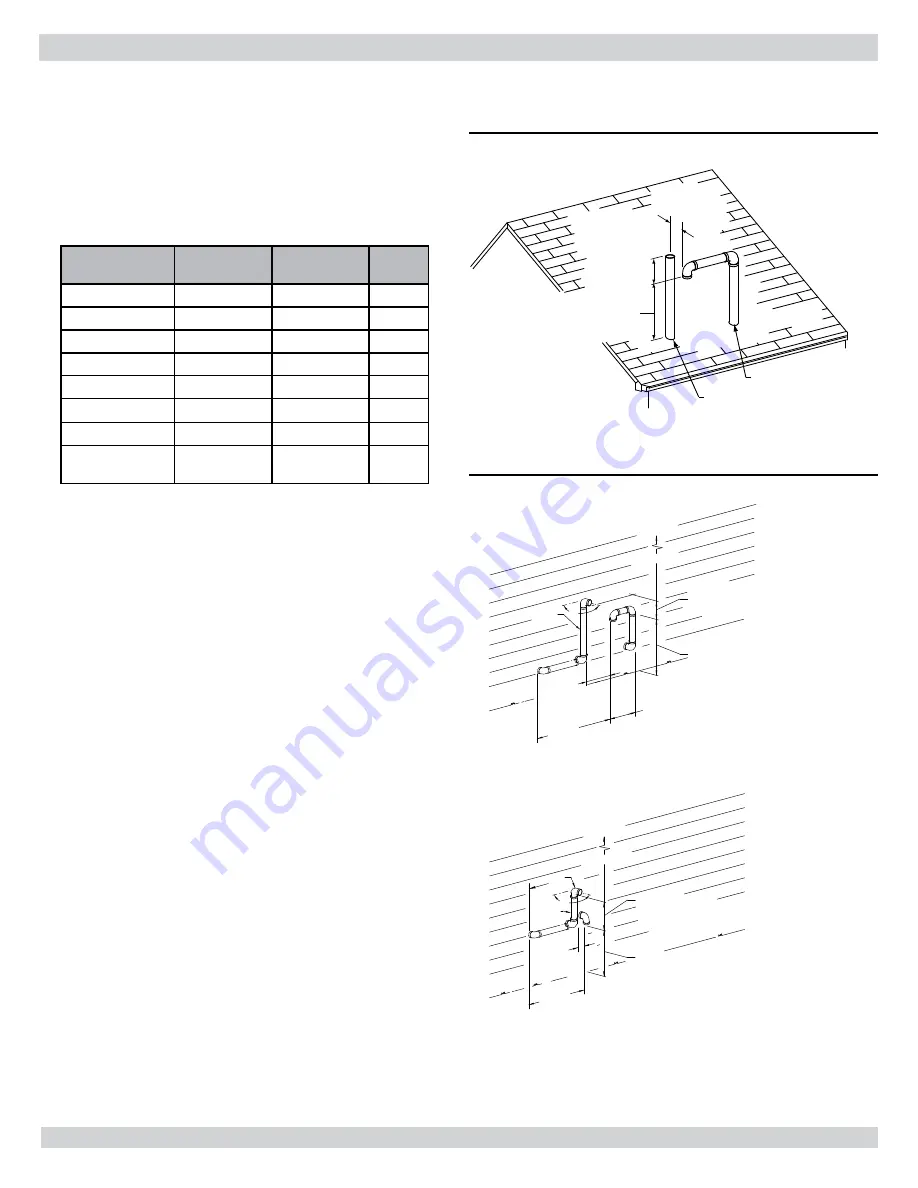

combustion air and vent pipe requirements

This boiler requires a dedicated direct vent system. In a direct vent

system, all air for combustion is taken directly from outside atmo-

sphere, and all flue products are discharged to outside atmosphere.

Combustion air and vent pipe connections must terminate together

in the same atmospheric pressure zone, either through the roof or

sidewall (roof termination preferred). See

Figures 1 and 2

for re-

quired clearances. If necessary, use of screening no smaller than 1/2”

hardware cloth is acceptable.

COMBUSTION AIR

EXHAUST

3” MAX.

8” MAX.

12” MIN ABOVE

HIGHEST ANTICIPATED

SNOW LEVEL

figure 1 - roof vent/intake terminations

OVERHANG

12" MINIMUM

90°

VENT

12" SEPARATION

BETWEEN BOTTOM OF

COMBUSTION AIR INTAKE

AND BOTTOM OF VENT

12" SEPARATION

BETWEEN BOTTOM OF

COMBUSTION AIR INTAKE

AND BOTTOM OF VENT

MAINTAIN 12" MINIMUM

CLEARANCE ABOVE HIGHEST

ANTICIPATED SNOW LEVEL OR

GRADE

MAINTAIN 12" MINIMUM

CLEARANCE ABOVE HIGHEST

ANTICIPATED SNOW LEVEL OR

GRADE

MAX.

SEPARATION

18"

MAXIMUM

15"

MAXIMUM

LESS THAN 12" CLEARANCE ABOVE GRADE

12" OR MORE CLEARANCE ABOVE GRADE

90°

BRACKET

VENT

18"

MAXIMUM

12" MINIMUM

OVERHANG

3"

MAXIMUM

SEPARATION

3”

figure 2 - sidewall vent/intake terminations

6

Summary of Contents for UTICA BOILERS UB95M-200

Page 26: ...26 ...

Page 45: ...45 ...

Page 46: ...46 ...

Page 47: ...NOTES ...

Page 48: ...Date Service Performed Company Name Tech Initials Company Address Phone ...