13

LOCATING THE BOILER

1. Place boiler at a location as centralized to the

piping system and as close to the chimney or vent

terminal as possible to minimize condensation.

At input rates up to 1.75 gph (245,000 Btu/hr),

the supply and return from radiation may be

piped on the same end of the boiler. At higher

rates, it is recommended that the supply be

piped from the rear of the boiler and the return

be piped from the front of the boiler. Coordinate

jacket installation with piping.

See

“Jacket

Assembly Instructions”

and

“Piping Diagrams”

in this manual for more information.

2. See

Figure #4

for installation on combustible

flooring. If necessary, place metal shims beneath

feet to ensure a level unit.

3. Accessibility clearances must take precedence

over fire protection clearances. Allow at least

24” for servicing at the tankless and burner

sides of the unit. Allow at least 18” at a side

where passage is required for access to

another side for servicing. A 6” clearance from

combustible material on all sides and the top

is recommended. 18” clearance is necessary

between smoke pipe and nearest combustible

material. See NFPA 31, latest revision, for safe

methods to reduce clearances where necessary.

NFPA publications are available at Battery Park,

Quincy, MA 02269.

CONSULT FIRE AUTHORITIES

FOR LOCAL REQUIREMENTS

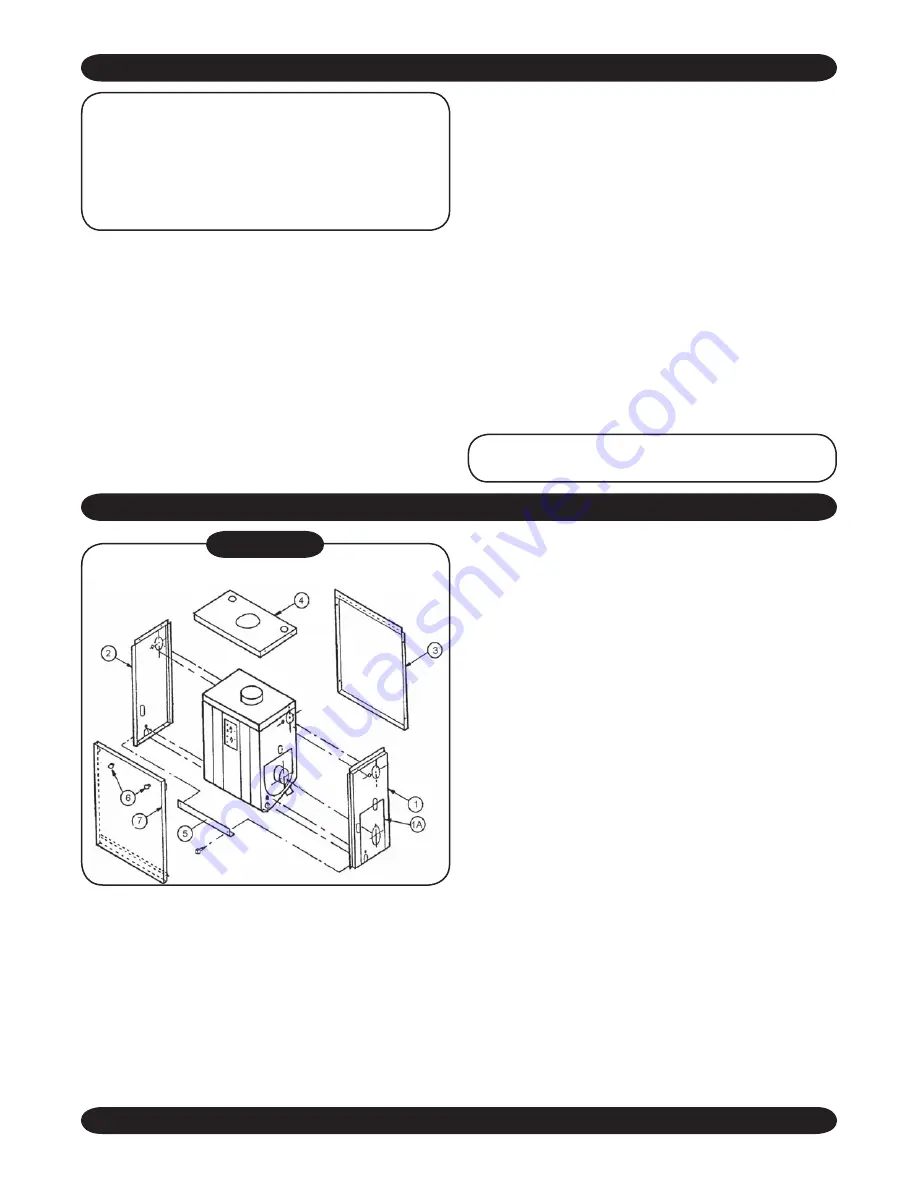

JACKET ASSEMBLY

(Indoor Boilers)

JACKET ASSEMBLY

(INDOOR BOILERS)

1. See

Figure #5

(above) for reference. Note that

all sheet metal screws are #10 unless specified

otherwise.

2. See hardware package in boiler accessory kit for

stand-off bolts, studs, acorn nuts, washers, and

⅛” pipe plug. Note that the sight glass assembly

is also found in the boiler accessory kit.

3. Screw double end stand-off bolts into castings

next to upper supply and lower return tappings

in both ends of the boiler. Screw three

5

/

16

” studs

finger-tight into burner mounting.

4. Hold panels 1 and 1A against burner end of

boiler and insert necessary piping through

jacket openings into boiler casting.

5. Screw acorn nuts onto stand-off bolts.

6. Screw 1” nipple and sight glass holder into hole

above burner.

7. Screw the ⅛” plug into tapping on upper left of

burner mounting.

8. Install panel 2 on opposite side of boiler in same

manner as panel 1.

9. Install panel 3 by attaching it with four sheet

metal screws to panels 1 and 2 (already in

position).

10. Install temperature/pressure gauge into either of

the two ¾” tappings on top of the casting. Using

a ¾” x 4½” nipple, install relief valve in second

top tapping. Install jacket top panel (#4) by

attaching it with four sheet metal screws to the

three jacket side panels already in position.

To permit easy disassembly of overflow pipe in

order to raise jacket top panel for annual cleaning,

screw hand tight a ¾” nipple into the relief valve.

Attach a ¾” elbow to the nipple and an overflow

NOTE:

Please see the separate Venting

Instruction for flue size limitation and other

information on venting. For direct exhaust

systems, the total run of horizontal flue pipe

must not exceed 6’ and the total run of vertical

flue pipe must not exceed 10’.

Figure #5

Summary of Contents for ULTIMATE PF Series

Page 2: ......

Page 16: ...16 BURNER WIRING RIELLO BURNER WIRING...

Page 17: ...17 MULTI ZONE SYSTEM WIRING AND PIPING...

Page 18: ...18 MULTI ZONE SYSTEM WIRING AND PIPING...

Page 19: ...19 PIPING WITH CIRCULATORS MULTI ZONE SYSTEM WIRING AND PIPING...

Page 20: ...20 MULTI ZONE SYSTEM WIRING AND PIPING...

Page 38: ...38 BOILER PARTS...

Page 44: ......