29

18. Referring again to

Figure #10

, fasten front jacket

panel (#9) in position with sheet metal screws and

install jacket top (#5).

19. Install exhaust assembly with parts 6, 7, and

8. The exhaust cap is made to spring inside the

short length of smoke pipe. A tourniquet made of

wire or a large hose clamp may be used to reduce

the diameter so that it will fit inside the pipe. Two or

three hose clamps in series may be used when a

large one is not available.

ANTIFREEZE

1. Antifreeze added to boilers must be non-toxic and

must be of a type specifically intended for use in closed

hydronic heating systems. Under no circumstances

should automotive antifreeze be used.

2. Use of antifreeze in any boiler may reduce capacity

by 10% or more and increase fuel consumption.

Tankless coil performance will fall as concentration

of antifreeze is increased.

3. Because antifreeze forms slush rather than hard

ice, it is safe to protect only to 10 degrees above

coldest temperature anticipated provided slush

formed can move towards expansion tank.

WATERPROOF (OUTDOOR) BOILER ASSEMBLY AND PIPING

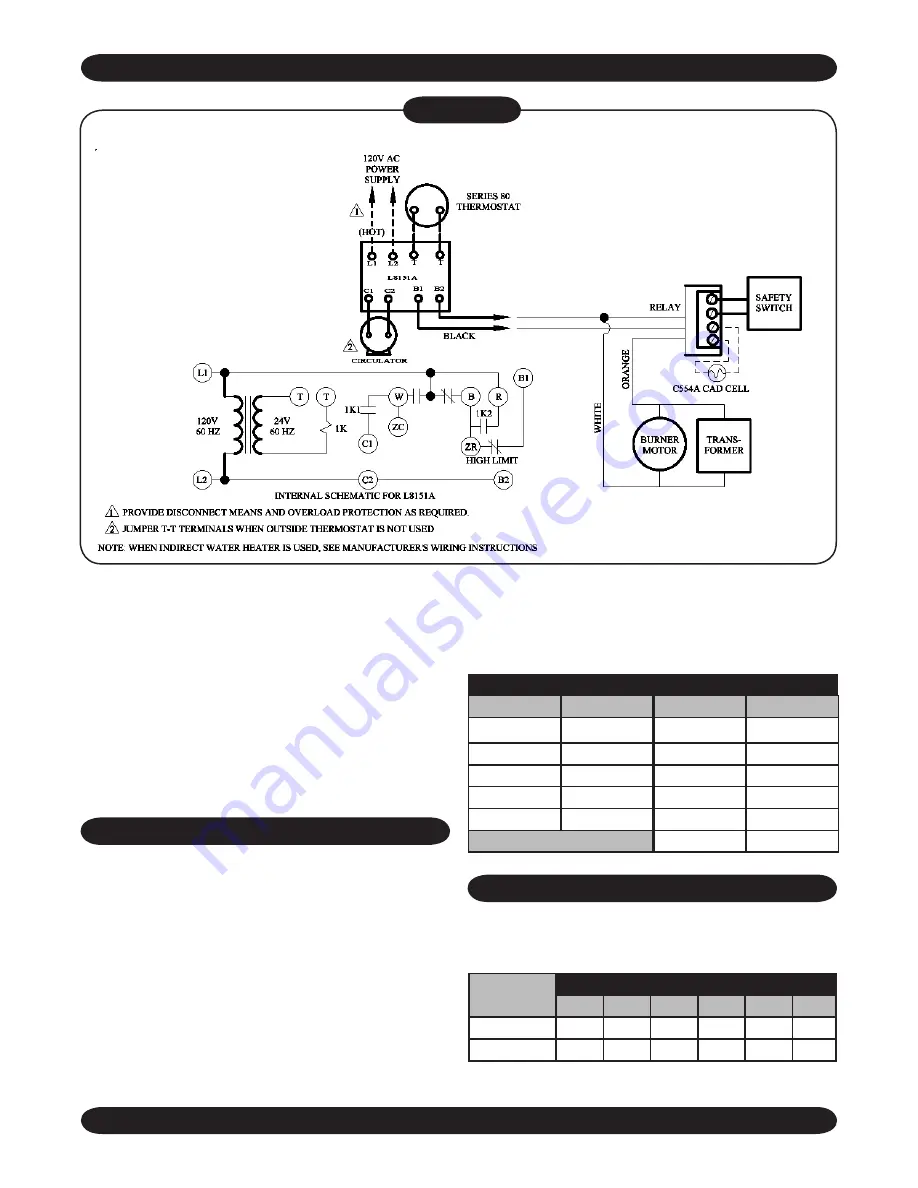

BECKETT BURNER WIRING DIAGRAM FOR WEATHERPROOF OIL-FIRED BOILER

(SPACE HEATING)

Figure #11

PIPE

MATERIAL

PIPE SIZE

½”

¾”

1”

1¼”

1½”

2”

COPPER

82.5

40.0

23.3

15.3

10.8

6.2

STEEL

63.5

36.0

22.2

12.8

9.5

5.8

WATER VOLUMES OF PF SERIES BOILERS

MODEL

VOL. (GAL.)

MODEL

VOL. (GAL.)

PF3

7

PF3T

10

PF4

9

PF4T

12

PF5

11

PF5T

14

PF7

15

PF6T

16

PF9

19

PF8T

20

PF7TT

21

PIPING VOLUMES

Divide total length of piping in feet by factor (below)

to determine water volume in gallons.

Summary of Contents for ULTIMATE PF Series

Page 2: ......

Page 16: ...16 BURNER WIRING RIELLO BURNER WIRING...

Page 17: ...17 MULTI ZONE SYSTEM WIRING AND PIPING...

Page 18: ...18 MULTI ZONE SYSTEM WIRING AND PIPING...

Page 19: ...19 PIPING WITH CIRCULATORS MULTI ZONE SYSTEM WIRING AND PIPING...

Page 20: ...20 MULTI ZONE SYSTEM WIRING AND PIPING...

Page 38: ...38 BOILER PARTS...

Page 44: ......