6

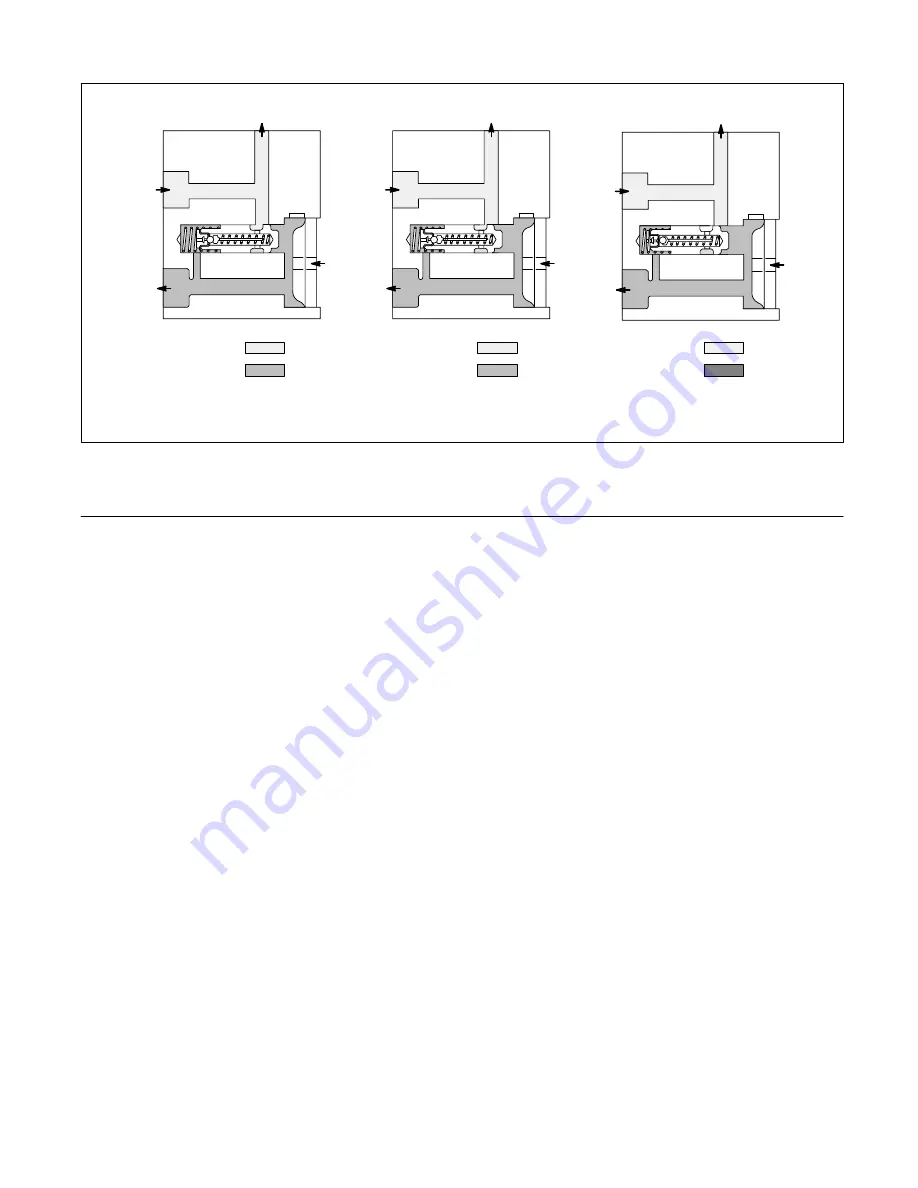

Figure 4.

A

All Pump

Delivery

B

Normal Operation

C

Operation causing excessive

pressure build-up

To Tank

Return

Port

Pressure

Port

Pressure

Code:

Return

Normal

From

Pump

To Tank

Return

Port

Pressure

Port

Pressure

Code:

Return

Normal

From

Pump

Pressure

Port

Return

Port

To Tank

From

Pump

Return

High

Pressure

Code:

Section IV - Installation and Operating Instructions

A. Drive Connections

Care must be exercised in pump mounting to insure correct

alignment with the driving medium. If indirect drive is used,

belts and pulleys must be properly aligned and adjusted to

prevent undue side loads being imposed on the shaft

bearings.

B. Shaft Rotation

1. Pumps are manufactured for either right hand or left

hand rotation. They must be driven in the direction of the

arrow on the pump ring or severe damage may result.

2. The direction of rotation can be changed by reversing

the pump ring and replacing the pressure plate with the cor-

rect plate for the desired direction of rotation (see parts cata-

log M-1370-S). Correct disassembly and assembly proce-

dures are given in Section VI of this manual.

C. Hydraulic Tubing

1. The number of bends in tubing must be kept to a mini-

mum to prevent excessive turbulence and friction of oil flow.

2. Tubing must not be bent too sharply. The minimum

radius for bends is three times the inside diameter of the

tube.

3. To minimize flow resistance and the possibility of leak-

age, only as many fittings and connections as are necessary

for proper installation should be used.

4. Tubing must not be sprung into position or undue

strain will result at the connections.

5. All tubing must be thoroughly cleaned before installa-

tion to remove dirt, rust and scale. Recommended methods

of cleaning are sand blasting, wire brushing and pickling.

D. Hydraulic Fluid Recommendations

1. Oil Type - Oils used in hydraulic systems perform the

dual function of lubrication and transmission of power. Oil

must be selected with care and with the assistance of a

reputable supplier.

Crankcase oils meeting or exceeding the ”Five Engine Test

Sequence” for evaluating oils for API (American Petroleum

Institute) service MS (Maximum Severity) best serve the

needs of mobile hydraulic systems. These engine sequence

tests were adopted by the Society of Automotive Engineers,

American Society for Testing Materials, and automotive

engine builders. The MS Classification is the key to selection

of oils containing the type of compounding that will extend

the operating life of the hydraulic system. Oils meeting

Diesel engine requirements, DG and DS classifications, may

or may not have the type of compounding desired for high

performance hydraulic systems.