7

Good oils are the most economical. Specifications can be set

up which will indicate, to a limited degree, the characteristics

essential in a good hydraulic oil. These are listed herein and

should be checked with the oil manufacturer prior to the use of

this product.

2. Viscosity - Viscosity is the measure of fluidity. The oil

must have sufficient body to provide adequate sealing effect

between working parts of pumps, valving, cylinders, etc., but

not enough to cause pump intake cavitation, sluggish valve

action, or in extreme cases, resistance to flow. Viscosity rec-

ommendations must at best be a compromise, which takes

into consideration the working temperature range, the type of

hydraulic equipment used, and the class of service. Refer to

table of oil viscosity recommendations below.

3. Viscosity Index - The viscosity index is a measure of

the rate at which temperature changes cause a change in oil

viscosity. It is very desirable that the oil viscosity remain as

nearly constant as possible under the wide range of temper-

ature conditions encountered in operating mobile and

construction machinery. The viscosity index (V.I.) of hydraulic

oil should not be less that 90 for this type of service.

4. Additives - Research has developed a number of

additive agents which materially improve various characteris-

tics of oils for hydraulic systems. They may be selected for

compounding with a view toward reducing wear, increasing

chemical stability, inhibiting corrosion, depressing pour point

and improving the anti-foam characteristics. Proper use of

additive agents requires specialized knowledge, and they

should be incorporated by the oil manufacturer only, as

serious trouble may otherwise result.

Most oil companies have several brands of crankcase oils of

somewhat varying formulation that will meet the API service

classification of MS. The more desirable of these oils for

hydraulic service will contain higher amounts of the type of

compounding that avoids scuffing and wear of cam lobes

and valve lifters. These oils will also be formulated to be

stable under oxidative conditions and when in contact with

small amounts of moisture. There should also be reasonable

protection against rust to any ferrous materials submerged in

the oil or covered by the oil’s film.

5. Cleanliness - Thorough precautions should be taken to

filter the oil in the entire hydraulic system prior to its initial use

to remove paint, metal chips, welding shot, lint, etc. If this is

not done, damage to the hydraulic system will probably result.

In addition, continuing filtration is required to remove sludge

and products of wear and corrosion, throughout the life of the

system.

Precautions should be taken in the design of hydraulic

circuits to assure that a means is provided to keep the oil

clean. This can best be accomplished by the use of a 25

micron full-flow filter or a 10 micron by-pass filter (not a

strainer) and a micronic air breather or sealed reservoir.

6. Pump Inlet Conditions - Use of an improper grade of

oil or restrictive inlet piping may result in inlet vacuum condi-

tions exceeding the recommended maximum 5 inches of

mercury, and will reduce the life expectancy of the hydraulic

equipment. Where vacuum exceeds 5 inches of mercury,

and it is not caused by improper oil selection, Vickers is to

be consulted.

7. Operating Temperatures - Operation in excess of

180

°

F. results in increased wear of the system components

and causes more rapid deterioration of the oil. The hydraulic

system that is designed to maintain a temperature of 160

° F.

or less desirable.

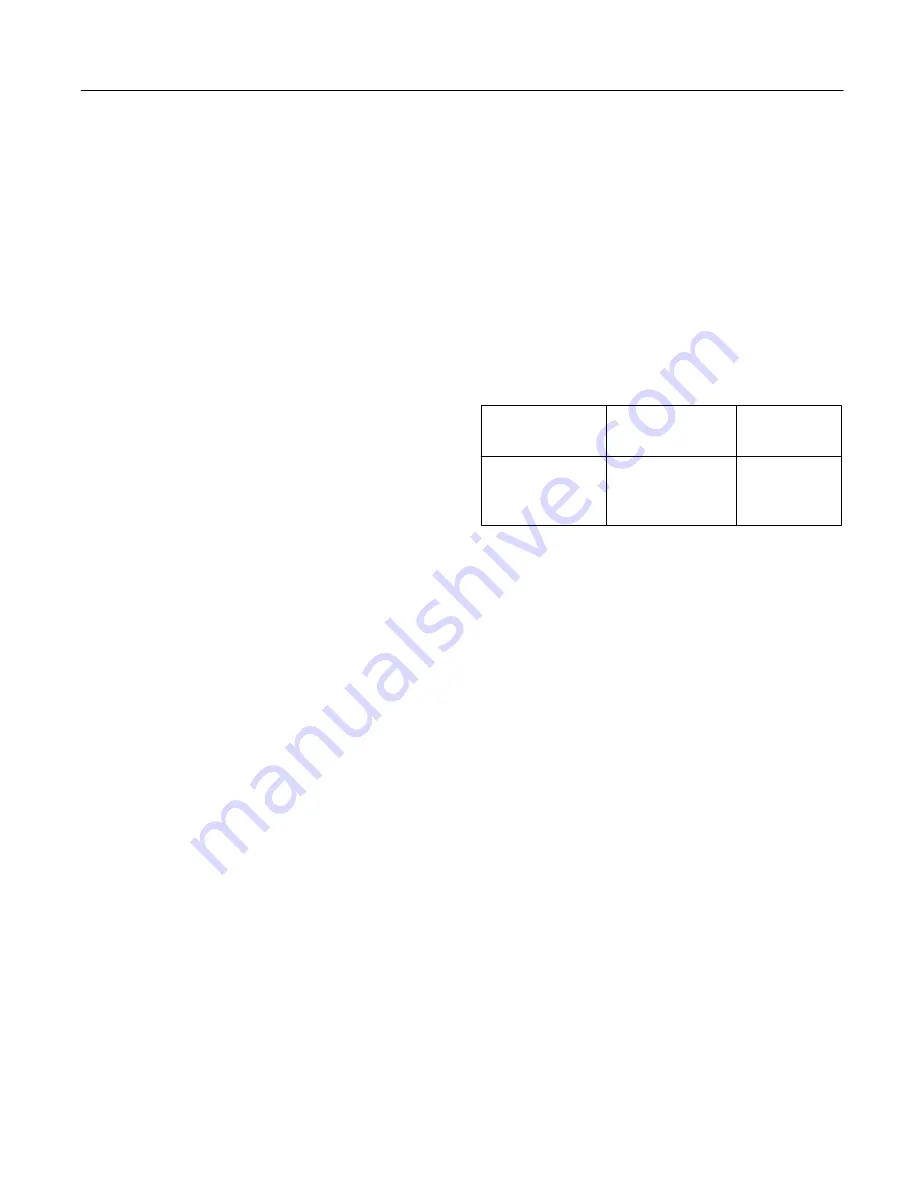

8. Grade - Table 3 summarizes the oil types (viscosity

and service classification) that are recommended for use

with Vickers equipment. This selection is most important and

should be made with considerable care.

Hydraulic System

Operating Range

(Min. to Max.)

SAE

Viscosity

API Service

Classification

0

°

F. to 180

°

F.

15

°

F. to 210

°

F.

32

°

F. to 230

°

F.

0

°

F. to 210

°

F.

10W

20-20W

30

10W-30

MS

MS

MS

MS

Table 3.

These temperature ranges for each grade of oil are

satisfactory if suitable procedures are followed for low

temperature start-up conditions and if sustained operation is

avoided at the upper temperature limits. For optimum

operation, a maximum oil viscosity of 4000 SSU at low

temperature start-up condition and a minimum oil viscosity of

60 SSU for sustained high temperature operating condition

are recommended. Operation of the fluid at temperatures

below 160

°

F. is recommended to obtain the maximum unit

and fluid life.

Automatic Transmission Fluid, Type “A” is usually satisfactory

for power steering systems or those systems operating under

moderate hydraulic service.

E. Overload Protection

1. An integral relief valve protects the hydraulic system

components by limiting the maximum pressure.

2. Relief valve sub-assemblies are pre-set and tested by

Vickers for given pressure settings. Selection of the correct

setting should be based on the system work requirements. If

the relief setting must be changed, a replacement valve

should be installed.