P-164000476

9395P 500kVA / 600 kVA

18

Revision 002

User’s and Installation Guide

3.2.2 UPS system power wiring preparation

NOTE

If installing, as part of the UPS system, a maintenance bypass without a rectifier input breaker, a

minimum of two separate feeds with upstream feeder breakers, or one feed with two upstream

feeder breakers, must be provided: one for the UPS and one for the maintenance bypass input.

DO NOT use one feed or a single feeder breaker to supply both the UPS and the maintenance

bypass.

For external wiring requirements, including the minimum size of external wiring, see Table 3-4 and

Table 3-5. The power wiring connections for this equipment are rated at 70°C. If wire is run in an

ambient temperature greater than 30°C, higher temperature wire and/or larger size wire may be

necessary.

NOTE

Callout letters A, B, C, and D map to the figures in Section 6.3 on page 75.

Bypass wiring data is not applicable to Input Output Module (IOM) configurations.

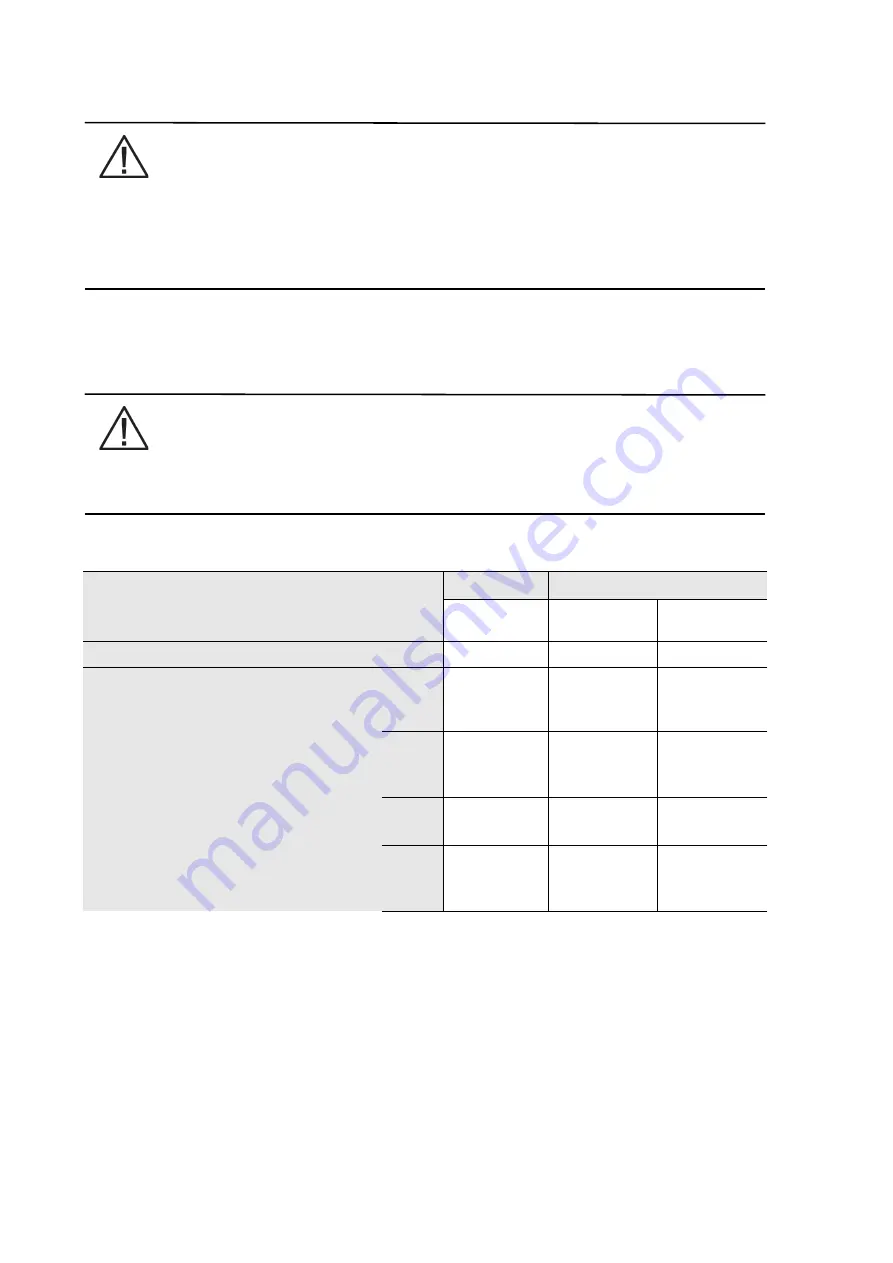

Table 3-4: Input/output rating for 9395P 500 kVA / 600 kVA

Units

Rating 50/60 Hz

Rating

kVA

kW

500 (2*250)

500 (2*250)

600 (2*300)

550 (2*275)

Input and output voltage

Volts

400/400

400/400

AC input to UPS rectifier

Full load current plus battery recharge current

(3) phases, (1) ground

A

Amps

894

983

AC Output to UPS Bypass

Full load current

(3) phases, (1) neutral–if required, (1) ground

B

Amps

722

866

DC input from battery to UPS

(1) positive, (1) negative

C

Amps

1313

1444

AC output to critical load

full load current

(3) phases, (1) neutral–if required, (1) ground

D

Amps

722

866

Summary of Contents for Power Xpert 9395P

Page 1: ...User s and Installation Guide Power Xpert 9395P UPS 500 kVA 600 kVA P 164000476 ...

Page 2: ...P 164000476 9395P 500kVA 600 kVA 2 Revision 002 User s and Installation Guide ...

Page 18: ...P 164000476 9395P 500kVA 600 kVA 8 Revision 002 User s and Installation Guide ...

Page 37: ...P 164000476 9395P 500kVA 600 kVA 27 Revision 002 User s and Installation Guide ...