24

25

INM MTL9373-FB3 Rev 1

INM MTL9373-FB3 Rev 1

NOTE

The Power LED will not light until the voltage at the barrier has risen to a value of

at least 15.7V, but could remain lit even after the voltage has dropped to around

13.0V. DO NOT assume the Power LED indicates a voltage of 16V or more.

If the green Power LED is not lit, check:

• the polarity and integrity of the trunk cable connections to the enclosure.

• that the d.c. supply powering the incoming trunk is operating correctly.

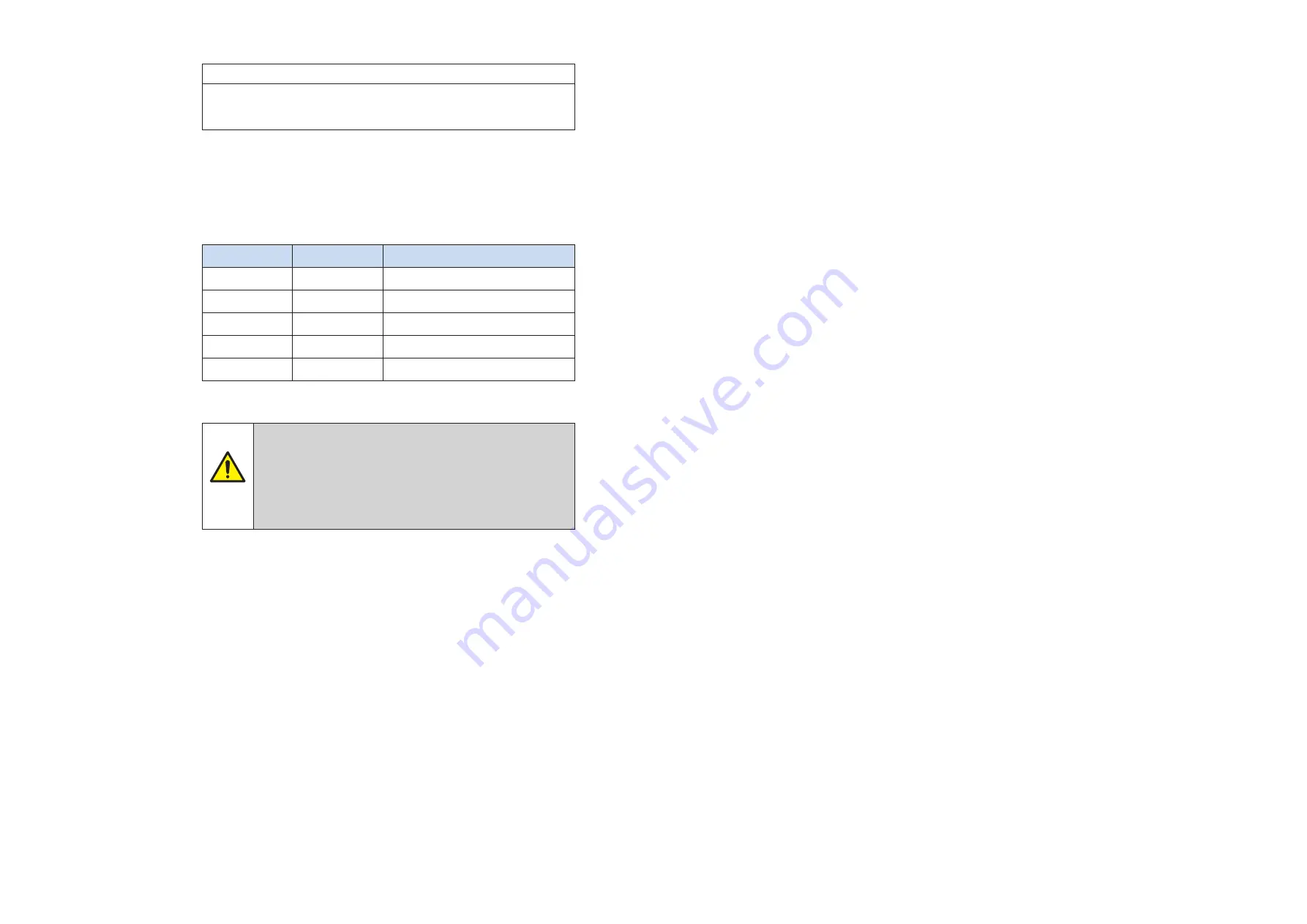

Spur LEDs

Colour

State

Description

Green

Steady

Channel powering spur, spur OK

Green

Flashing

Channel powering spur, spur open

Red

Steady

Internal fault

Orange

Steady

Short to shield

Orange

Flashing*

Short circuit, current limit

* Flashing occurs at a rate of approximately 2 pulses per second.

CAUTION!

9373-FB3 Fieldbus Barrier modules are designed to operate reliably

in industrial environments and comply with international standards for

immunity to electromagnetic radiation. However, damage may occur if

the apparatus is exposed to extreme levels of radiated electrical noise,

for example from “walkie-talkie” radios, or electric arc-welding. If local

welding activity is unavoidable, power should first be removed from

the module.

8

ATEX INFORMATION

The Essential Health and Safety Requirements (Annex II) of the EU Directive

2014/34/EU [the ATEX Directive - safety of apparatus] requires that the installation

manual of all equipment used in hazardous areas shall contain certain information.

This annex is included to ensure that this requirement is met. It complements the

information presented in this document and does not conflict with that information.

It is only relevant to those locations where the ATEX directives are applicable.

8.1 General

a) In common with all other electrical apparatus installed in hazardous areas,

this apparatus must only be installed, operated and maintained by competent

personnel. Such personnel shall have undergone training, which included

instruction on the various types of protection and installation practices, the

relevant rules and regulations, and on the general principles of area

classification. Appropriate refresher training shall be given on a regular basis.

[See clause 4.2 of EN 60079-17].

b) The apparatus has been designed and manufactured so as to provide

protection against all the relevant additional hazards referred to in Annex II of

the Directive, such as those in clause 1.2.7.

c) This apparatus has been designed to meet the requirements of electrical

apparatus in accordance with EN 60079-0, EN 60079-7, EN 60079-11 and

EN 60079-18.

8.2 Installation

a) The installation should comply with the appropriate European, national and

local regulations, which may include reference to the IEC code of practice

IEC 60079-14. In addition, particular industries or end users may have specific

requirements relating to the safety of their installations and these

requirements should also be met. For the majority of installations, the

Directive 1999/92/EC [the ATEX Directive – safety of installations] is

also applicable.

b) The equipment is certified: Baseefa19ATEX0023X and is designed for

installation in Zone 1, Zone 2, Zone 21 or Zone 22 hazardous areas if mounted

in a suitable enclosure.

c) The apparatus must not be subjected to mechanical and thermal stresses in

excess of those permitted in the certification documentation, this manual and

the product specification.

d) All cables and their glands must be chosen to withstand the temperatures at

which the apparatus is designed to operate. See product specification

for details.

e) The apparatus must not be installed in a position where it may be attacked by

aggressive substances.

Read also the Special Conditions for Safe Use (below) for any additional or more

specific information.

8.3 Special Conditions for Safe Use

1. The equipment shall only be powered from supplies conforming to IEC 61158.

2. When a TP32 Trunk Surge Module is fitted, the power input circuit will not

withstand a 500V a.c. isolation test to earth. This must be taken into account

during installation.

3. When one or more FS32 Spur Surge Modules are fitted, the spur outputs will

not withstand a 500V a.c. isolation test to earth. This must be taken into

account during installation.

4. When the enclosure is fitted with a hinged lid, it shall only be mounted in a

vertical orientation on a flat surface, and care is required in the installation

process and when opening the hinged lid to ensure the enclosure does

not distort.

continued