6

General Information

ControlKeeper 4

scheduling the hardware override switch must be in the

AUTO or center position. See Figure 9 for location of the

hardware override switch.

LED Operation

The ControlKeeper 4 has LEDs for status monitoring. They

consist of System Status LEDs and Relay Status LEDs.

System Status LEDs

Status

Power

Network

Digita Switch

ControlKeeper® 4 Upper Left Corner

Relay Status LEDs

Relay 1 Through 4

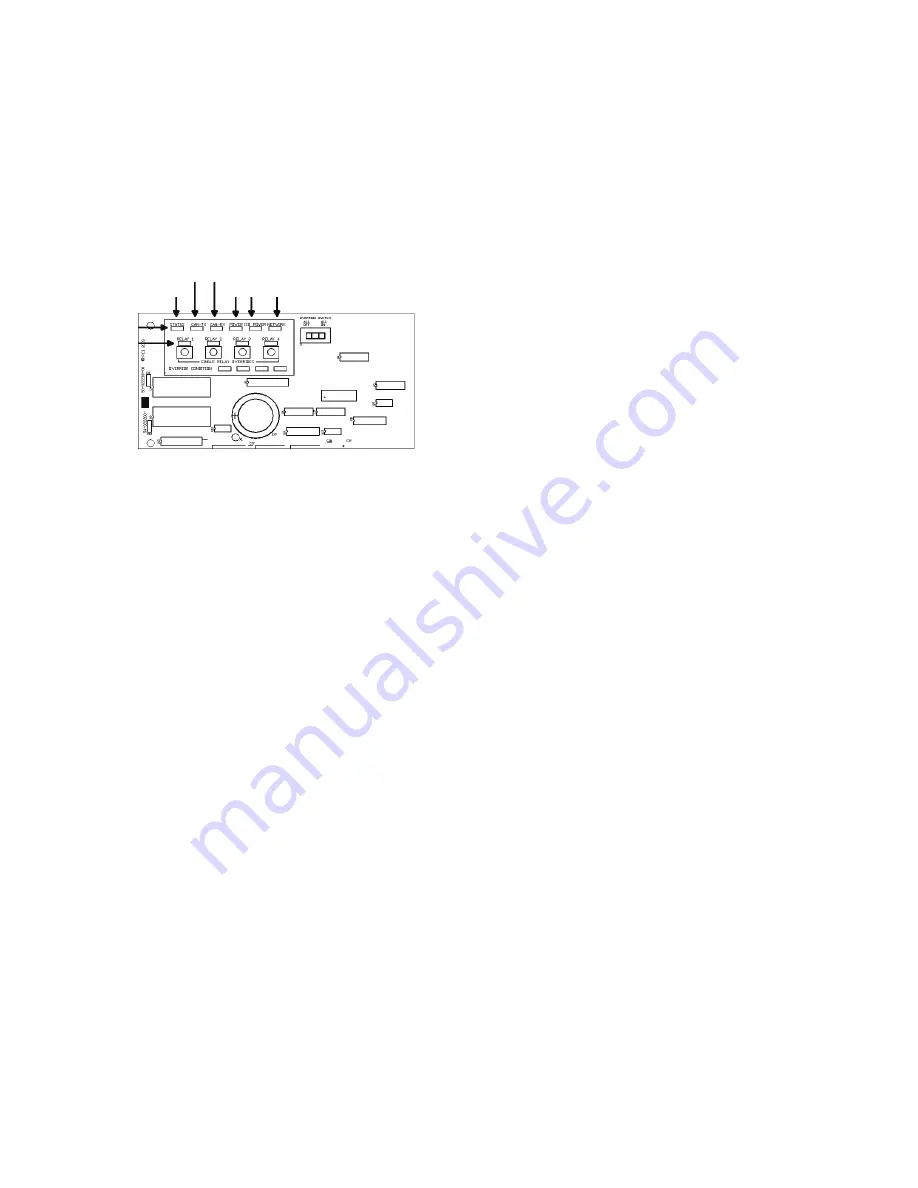

Figure 11. ControlKeeper 4 Status LEDs

System Status LEDs

There are six (6) system status LEDs that are located in the

upper left corner of the ControlKeeper 4. Please refer to

Figure 10 for location of these status LEDs. These status

LEDs will indicate proper operation or potential problems

with the ControlKeeper 4. Normal Operation includes the

following LED states.

Status LED:

The Status LED will flash ON and OFF continuously

under normal operation. The LED is an indication of

microprocessor health. If the LED is ON or OFF all the time,

please use the soft reset button on the controller. If the LED

does not resume normal flashing state, contact Technical

Support.

Digital Switch LEDs:

These LEDs, labeled CAN-TX and CAN-RX, will flash when

Digital Switch information is being passed back and forth

between the Digital Switch Gateway and the ControlKeeper

4.

Power LEDs:

These LEDs, labeled POWER and ISO POWER, indicate that

the ControlKeeper 4 is getting the proper expected voltage

from the transformer. If one or both of these LEDs is not lit,

there is a problem with power to the board. Please contact

Technical Support for further details.

Network LED:

The Network LED should flash only when activity is present

on the network wire. If communications commands are not

being transmitted over the network wire from the Keeper

Enterprise Software or broadcast switches and this LED

is flickering, ON constant, or flashing, it is an indication of

noise on the network wire that may interfere with proper

system operation. Please check all network wiring carefully

for shorts to AC Ground if this condition exists. Contact

Technical Support for further troubleshooting help.

Relay Status LEDs

There are four relay status LEDs, one for each of the

relays on the ControlKeeper 4. Please refer to Figure 10

for location of these LEDs. The relay status LEDs are an

indication of whether the associated relay is energized or

de-energized. If the relay LED is ON, the relay load should

be ON. If the relay LED is OFF, the relay load should be OFF.

ControlKeeper 4 RS232 Port

The ControlKeeper 4 has an on board RS232 port for

communications to peripheral accessory devices or to

the Keeper Enterprise Software. This RJ style jack should

not be connected to any device not intended for use with

the lighting control system. Connection to a phone line

will cause damage to the lighting control system that is

not covered under warranty. Please use only Greengate

approved device connections for connection to this port.

System Reset and Clear Commands

Under certain circumstances, you may want to reset the

ControlKeeper 4. There are two different types of reset

commands available in the ControlKeeper 4 system: a soft

reset command and a clear reset command.

Soft Reset Command:

A soft reset command is used to initialize a new

panel address with the panel. It can also be used as a

troubleshooting technique if the panel is not responding or

to free up the microprocessor if the unit’s STATUS LED is

not flashing. The Soft Reset Command will not cause loss

of panel programming. To perform a Soft Reset Command,

press in and then immediately release the reset button in

the lower right corner of the logic panel. When the reset

button is pressed and released, the status LED may hesitate

briefly then resume normal operation.

Clear Settings Command:

A clear settings command is used to remove all

programming from a ControlKeeper 4 unit. It should be

done before downloading programming to the unit for

the first time or when asked to by a Technical Support

representative. Please use caution with this command!

When performing a Clear command, all relay loads will turn

OFF. Use the Hardware Override Switch to keep lighting ON

if necessary.

In order to reprogram the unit, you will need to use the

Keeper Enterprise Software. To perform a Clear Command,

press and hold down the reset button in the lower right

corner of the low voltage section for a period of 15 seconds