5

General Information

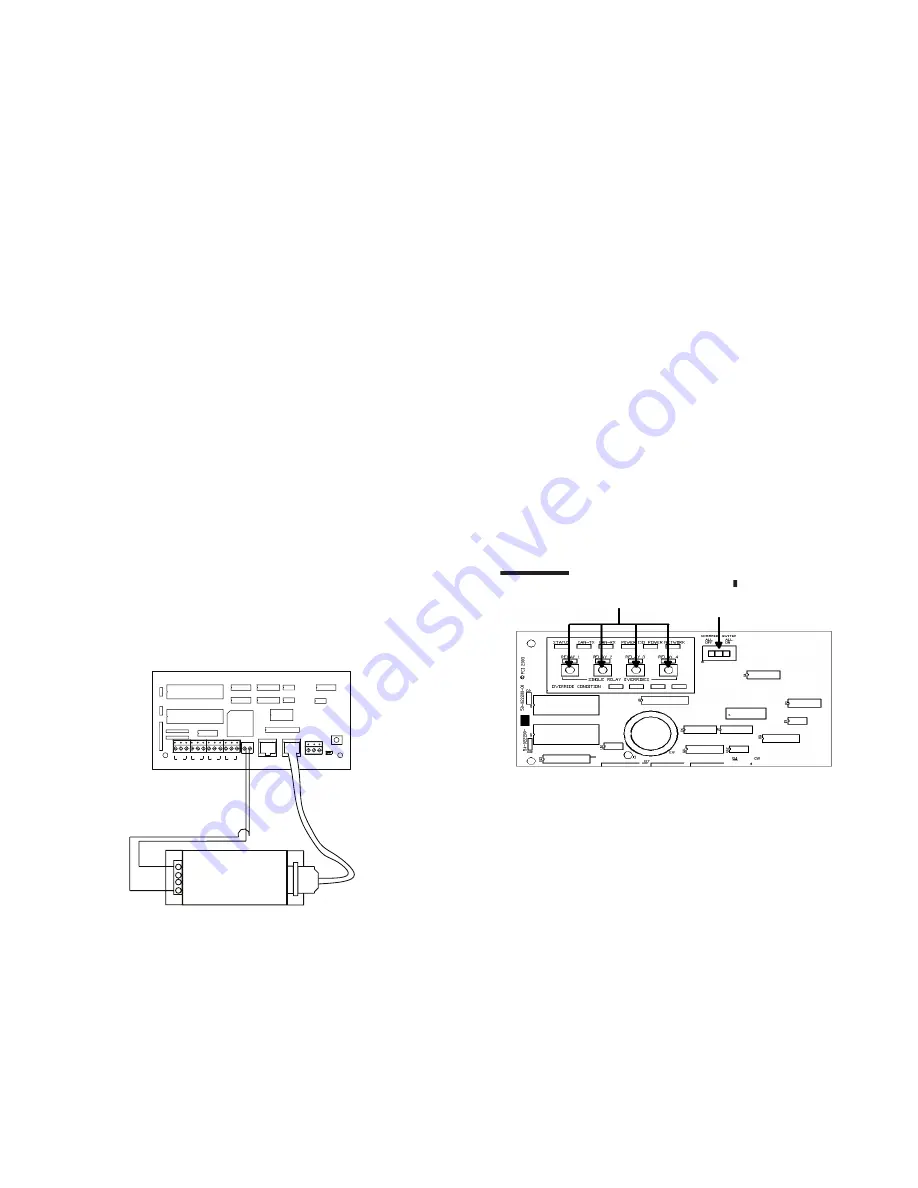

ControlKeeper 4

configuration. No T-Taps/Stars should be used. The GDS-I

device should reside somewhere within the daisy-chain

switch net work. Total daisy-chain network length should not

exceed 1000 feet.

The following instructions describe the GDS-I device

connection to the ControlKeeper 4. Please refer to the

Digital Switch Installation Instructions for information on

wiring the Digital Switch network to the GDS-I.

1. Mount the GDS-I next to the ControlKeeper 4 panel.

A six foot phone style cable has been provided for

connectionto the ControlKeeper 4 panel.

2. Run a length of the Digital Switch LC or Belden cabling

from the GDS-I location to the low voltage section of

the ControlKeeper 4.

3. Connect the RED wire in the cable to the +V terminal

on the back of the GDS-I and to the ControlKeeper 4 at

one of the switch input +24VDC terminals.

4. Connect the BLACK wire in the cable to the GND

terminal on the back of the GDS-I and to the

ControlKeeper 4 remote power connector GND

terminal.

5. Tape back or cap the blue and white wires and shield

wire for the cable. They will not be used for connection

between the GDS-I and lighting controller.

6. Locate the 6 foot phone style cable included in the

GDS-I box. Run this from the GDS-I into the low voltage

section of the ControlKeeper 4 enclosure plugging the

end with 9 pin head into the GDS-I. Plug the end the

RJ11 phone style plug into the ControlKeeper 4.

-

+

NETWORK

RS232

VDC

DC

GND

+24

CH4

OFF

ON +24

CH3

OFF

ON +24

CH2

OFF

ON +24

CH1

OFF

ON +24

RESET

NET TERM

U28

U25

U26

U22

U24

U1

9

U20

U29

TB7

4

1

2 3

5 6

8

7

J2

J1

U1

8

U27

U23

U21

TB5

TB4

S7

RN1

J3

C26

C20

U1

7

Cabling is Eaton’s Cooper LC Cable,

Belden 1502R, or Belden 1502P

Wire Phone Style Cable to

RJ11 Jack on CK4 and to GDS-I

GDS-I

BLACK Wire From GDS-I

GND to CK4 GND

RED Wire From GDS-I V

+ to CK4 +24VDC

Figure 9. GDS-I Wiring Detail

Applying Power

1. After wiring is complete, make certain to clean panel

of all wire clippings and fragments ensuring that no

fragments get lodged between the circuit board and

enclosure.

2. Ensure that there are no loose wires or exposed wires

that could short out.

3. Make certain that the line voltage section of the

enclosure is closed and secure.

4. Power-up the unit. It is recommended that the unit be

cleared of all programming unless the unit has been

sent pre-programmed to you by the factory. To perform

this step, hold down the reset button for about

15 seconds.

5. Please refer to the operation section of this instruction

for information on turning ON and OFF lighting loads.

Refer to the Keeper Enterprise Software manual

for information regarding the programming of the

ControlKeeper 4 jumper.

Relay Override Operation

The ControlKeeper 4 has two means of override located

on the logic board: individual relay override buttons and a

hardware override switch. It is possible to control lighting

loads and override programming using these override

mechanisms.

Individual Relay

Override Switches

Hardware Override Switch

ControlKeeper® 4 Upper Left Corner

Figure 10. ControlKeeper 4 Status LEDs

Individual Relay Override Notes

Each relay on the ControlKeeper 4 may be overridden using

the individual relay override switches located at the top

left of the low voltage section. See Figure 9 for location

of these switches. These override switches will toggle the

associated relay’s state with each push of the button. This

type of over ride is temporary in that the override will last

until the next command that the relay is given.

Hardware Override Switch Notes

In addition to the individual relay override switches, there

is a hardware override switch that allows the override of

all relays on the board. If this switch is moved to the ALL

ON or ALL OFF position, all four relays will remain ON or

OFF as long as the switch is in that ALL ON or ALL OFF

position. The ON or OFF state is maintained regardless of

programmed state. In order for relays to run programmed