Installation Plan and Unpacking

Eaton

®

Power Xpert 9395 Integrated Battery Cabinet (Model 1085 and 1085HR) Installation Manual 164201687—Rev 06

www.eaton.com/powerquality

3-9

3.3

Inspecting and Unpacking the Battery Cabinet

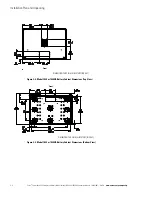

The battery cabinet is palleted separately for shipping. The cabinet is shipped bolted to a pallet consisting of

four angle metal supports secured to two four-inch by six-inch wood supports, as shown in Figure 3-5 and

protected with outer protective packaging material.

CAUTION

The battery cabinet is extremely heavy (see Table 3-1). If unpacking instructions are not closely

followed, the cabinet may tip and cause serious injury.

1.

Carefully inspect the outer packaging for evidence of damage during transit.

CAUTION

Do not install a damaged cabinet. Report any damage to the carrier and contact your service

representative immediately.

2.

Use a forklift or pallet jack to move the packaged cabinet to the installation site, or as close as possible,

before unpacking. Insert the forklift or pallet jack's forks between the pallet supports on the bottom of the

unit.

CAUTION

Do not tilt the UPS cabinet more than 10° from vertical or the cabinet may tip over.

3.

Set the pallet on a firm, level surface, allowing a minimum clearance of 3m (10 ft) on each side for

removing the cabinet from the pallet.

4.

Remove the protective covering from the cabinet.

5.

Remove the packing material, and discard or recycle in a responsible manner.

6.

Inspect the contents for any evidence of physical damage, and compare each item with the Bill of Lading.

If damage has occurred or shortages are evident, contact your service representative immediately to

determine the extent of the damage and its impact upon further installation.

NOTE

For the following step, verify that the forklift or pallet jack is rated to handle the

weight of the cabinet (see Table 3-1 for cabinet weight).

NOTE

The battery cabinet is shipped with a debris shield covering the ventilation grill on

top of the unit. Do not remove the debris shield until installation is complete.

NOTE

While waiting for installation, protect the unpacked cabinet from moisture, dust, and

other harmful contaminants. Failure to store and protect the UPS properly may void

your warranty.