EASTMAN

Form C-1572

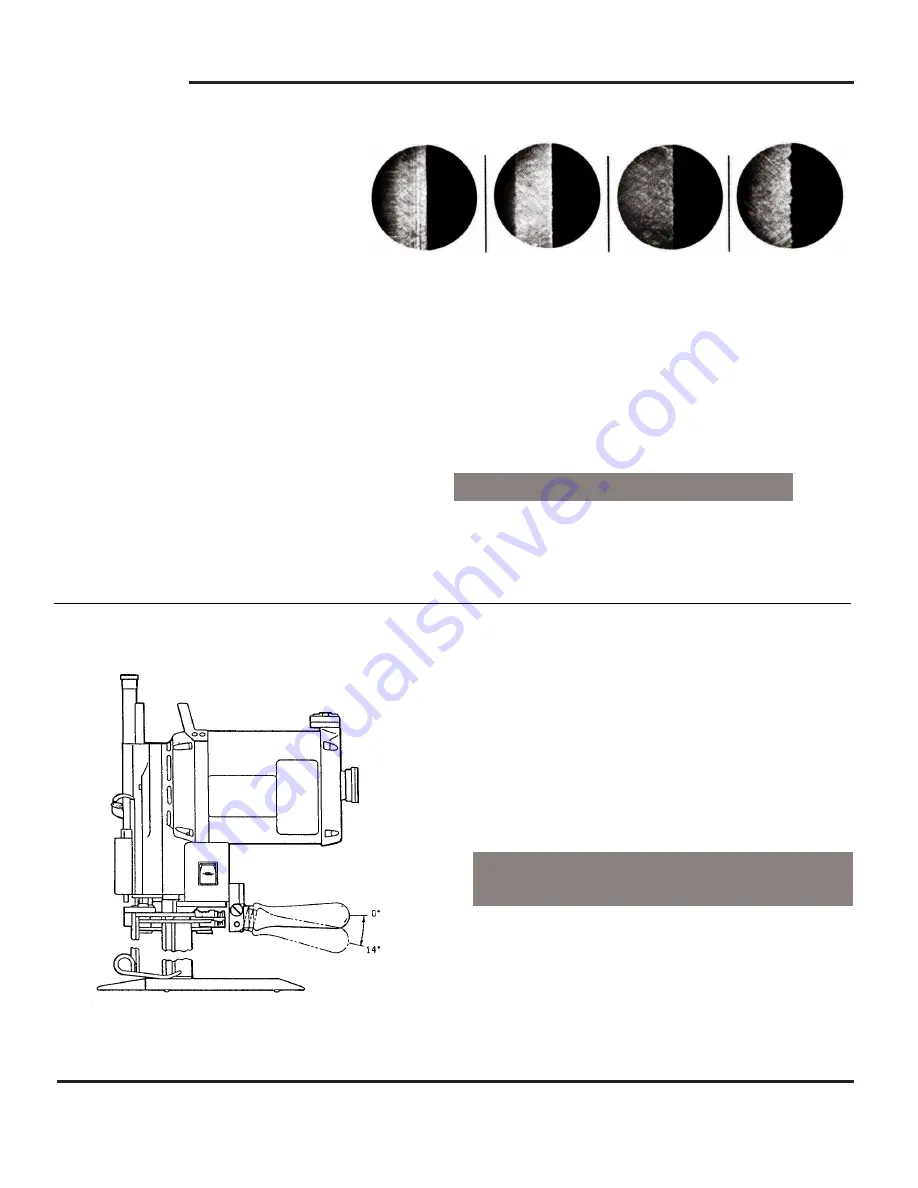

The 250X microphotographs (Figure 16)

show four different edges, as produced

by Eastman’s four abrasive belt grits.

FINE BELT

FINE EDGE

Slices thru

synthetics and

blends, for knitted

or loosely woven

cloths, and for

silks, high-pile

fabrics, quilting,

etc.

BLUE

181C2-5

MEDIUM BELT

MEDIUM EDGE

Shears thru the

general run of

rayons, cottons,

light woolens,

tropicals, suitings,

and similar

materials

GREEN

181C2-2

COARSE BELT

COARSE EDGE

For heavier weight

variations of the

"medium" materials

at left, and for

lightly woven

cloths, pocketing,

light denims,

over-coatings,

light leatherette,

and rubberized

fabrics

RED

181C2-1

ROUGH BELT

ROUGH EDGE

The edge that

practically SAWS

thru heavy denim,

coated fabrics,

treated canvas,

simulated heavier

leathers, etc.

where the going

gets tough!

BLACK

181C2-6

SPECIAL PERFORMANCE BELTS: Electrostatically Coated

FINE BELT

MEDIUM BELT

COARSE BELT

BLUE

GREEN

RED

181C2-5SP

181C2-2SP

181C2-1SP

Figure 16. Edges Produced by Different Belt Grits

Available as an option on new machines or for retrofitting to

any existing Eastman straight knife, the Ergo-Handle al-

lows the operator to adjust the handle downward from the

standard horizontal through a 14-degree range. Adjusting

the handle’s angle to suit the operator’s preference allows

for more effective use of the arm muscles, while placing

less strain on the wrist and thumb.

PART NO.

DESCRIPTION

531C1-87

Regular Ergo-Handle

531C1-88

Cushion Ergo-Handle

Ergo-Handle

Figure 17. Ergo-Handle

18