Summary of Contents for Extreme Series

Page 1: ...Service Manual E One Extreme Grinder Pumps 240V 60 Hz Hardwired Controls...

Page 2: ......

Page 32: ...Pump End 5 8 Figure 5 9a D Series Pump Exploded View...

Page 33: ...Pump End 5 9 Figure 5 9b W Series Pump Exploded View...

Page 34: ...Pump End 5 10 Figure 5 9c Gatorgrinder GH Series Pump Exploded View...

Page 35: ...Pump End 5 11 Figure 5 9d IH091 Pump Exploded View...

Page 36: ...Pump End 5 12...

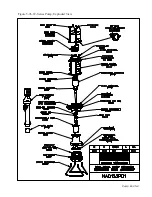

Page 58: ...Level Sensor 8 10 Figure 8 35 Level Sensor Assembly Exploded View all hardwired pumps...

Page 70: ...Mechanical Seal Assembly 11 2...

Page 75: ......