F 60.18 15

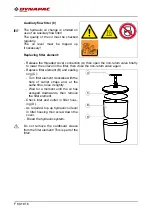

Marking hydraulic hoses / storage pe-

riod, period of use

A

A number stamped onto the screwed

connection provides information about

the date of manufacture (A) (month /

year) and the maximum pressure per-

mitted for this hose (B).

m

Never install hoses on top of one anoth-

er and always ensure that they are at the

correct pressure.

In individual cases, the period of use can

be stipulated according to experience

and may differ from the following general

indications:

- When producing the hose pipe, the hose (purchased by the meter) should not be

more than four years old.

- The period of use of a hose pipe should not exceed six years, including any possi-

ble storage period.

The storage period should not exceed two years.

DHH 03/11 225BAR

A

B

Summary of Contents for F1800C

Page 1: ...OPERATION MAINTENANCE Paver Finisher F1800C Type 910 03 1019 4812076575...

Page 2: ...www dynapac com...

Page 24: ...A 2...

Page 32: ...B 8 4 Safety devices 5 7 11 3 1 2 9 12 10 10 8 4 5 6 7...

Page 43: ...B 19 71 70 40 41 42 xxxxxxxxxxxxxxxxx 7 7 51 53 73...

Page 58: ...B 34...

Page 84: ...C 10 18 26...

Page 88: ...D 10 18 4 13 14 17 16 18 15 10 12 11...

Page 90: ...D 10 18 6 13 14 17 16 18 15 10 12 11...

Page 92: ...D 10 18 8 13 14 17 16 18 15 10 12 11...

Page 94: ...D 10 18 10 21 20...

Page 96: ...D 10 18 12 23 22...

Page 98: ...D 10 18 14 25 24...

Page 100: ...D 10 18 16 26 27...

Page 102: ...D 10 18 18 28 29...

Page 104: ...D 10 18 20 30 31...

Page 106: ...D 10 18 22 32 33...

Page 108: ...D 10 18 24 34 35...

Page 110: ...D 10 18 26 36 37...

Page 112: ...D 10 18 28 38...

Page 114: ...D 10 18 30 39 40 41 42...

Page 116: ...D 10 18 32 44 43...

Page 118: ...D 10 18 34 45 46 47...

Page 120: ...D 10 18 36 47...

Page 124: ...D 10 18 40 90 91 92 94 93 95 96 96...

Page 126: ...D 10 18 42...

Page 127: ...D 24 18 1 D 24 18 Operating the display...

Page 151: ...D 24 18 25 Example...

Page 154: ...D 24 18 28...

Page 159: ...D 30 18 5 Control platform telescoping seat consoles 10 B A B 11 6 4 5 2 8 A 9 7 12...

Page 192: ...D 30 18 38...

Page 197: ...D 40 18 5 1 9 2 5 5 3 4 6 7 8...

Page 199: ...D 40 18 7 1 9 2 5 5 3 4 6 7 8...

Page 202: ...D 40 18 10 1 2 3 4 5 6...

Page 204: ...D 40 18 12 2 3 6 5 7 1...

Page 206: ...D 40 18 14 2 2 3 1 6 5 4...

Page 210: ...D 40 18 18 A 1 3 2 4...

Page 212: ...D 40 18 20 1 2 5 6 7 4 11 10 3 12 9 8...

Page 215: ...D 40 18 23 3 1 2...

Page 217: ...D 40 18 25 1 2 3...

Page 219: ...D 40 18 27 1 3 14 2 15 5 8 4 9 7 6 5 4 11 10 12 13 16...

Page 226: ...D 40 18 34...

Page 243: ...F 31 18 1 F 31 18 Maintenance conveyor 1 Maintenance conveyor...

Page 250: ...F 31 18 8...

Page 251: ...F 40 18 1 F 40 18Maintenance auger assembly 1 Maintenance auger assembly...

Page 275: ...F 60 18 1 F 60 18 Maintenance hydraulic system 1 Maintenance hydraulic system...

Page 291: ...F 70 18 1 F 70 18 Maintenance drive units 1 Maintenance drive units...

Page 303: ...F 82 18 1 F 82 18 Maintenance electrical system 1 Maintenance electrical system...

Page 318: ...F 82 18 16...

Page 326: ...F 90 18 8...

Page 327: ...F 100 1 F 100 Tests stopping 1 Tests checks cleaning stopping...

Page 338: ...F 100 12...

Page 340: ...F 110 18 2 2 6 6 1 7 3 4 5...

Page 346: ...F 110 18 8...

Page 347: ......

Page 348: ...www dynapac com...