D 30.18 10

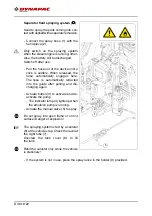

Driver's seat, type I

f

To avoid damage to health, the individu-

al seat settings should be checked and

adjusted before starting the vehicle.

f

After locking the individual elements, it

must no longer be possible to shift then

to another position.

-

Weight setting (1):

The relevant driv-

er's weight should be set by turning

the weight adjustment lever when the

driver's seat is unoccupied.

-

Weight indicator (2):

The set driver's

weight can be read off at the viewing

window.

-

Longitudinal adjustment (3):

Longi-

tudinal adjustment is released by actu-

ating the locking lever.

The locking lever must engage in the desired position.

-

Seat depth adjustment (4):

The seat depth can be individually adjusted. Raise the

button to adjust the seat depth. The desired position is set by simultaneously sliding

the seat surface forwards or backwards.

-

Seat inclination adjustment (5):

The seat surface's longitudinal inclination can be

individually adjusted. Raise the button to adjust the inclination. The seat surface in-

clines to the desired position by simultaneously loading or relieving it.

-

Armrest inclination (6):

The armrest's longitudinal inclination can be adjusted by

turning the hand wheel. Turning outwards raises the front of the armrest; turning

inwards lowers it at the front.

In addition, the armrests can be folded up fully.

-

Lumbar support (7):

Both the height and the extent of the convexity in the backrest

padding can be individually adjusted by turning the hand wheel to the left or right.

-

Backrest adjustment (8):

The backrest is adjusted via the locking lever. The lock-

ing lever must engage in the desired position.

-

Back extension (9):

By pulling out via perceptible detents, the height can be indi-

vidually adjusted up to a limit stop. To remove the back extension, the limit stop is

overcome with a jolt.

-

Seat heating ON/OFF (10):

The seat heating is switched on and off by actuating

the switch.

-

Seat belt (11):

The seat belt must be applied before starting up the vehicle.

f

The seat belts must be replaced following an accident.

3

7

10

4

5

6

6

8

11

1

9

2

Summary of Contents for F1800C

Page 1: ...OPERATION MAINTENANCE Paver Finisher F1800C Type 910 03 1019 4812076575...

Page 2: ...www dynapac com...

Page 24: ...A 2...

Page 32: ...B 8 4 Safety devices 5 7 11 3 1 2 9 12 10 10 8 4 5 6 7...

Page 43: ...B 19 71 70 40 41 42 xxxxxxxxxxxxxxxxx 7 7 51 53 73...

Page 58: ...B 34...

Page 84: ...C 10 18 26...

Page 88: ...D 10 18 4 13 14 17 16 18 15 10 12 11...

Page 90: ...D 10 18 6 13 14 17 16 18 15 10 12 11...

Page 92: ...D 10 18 8 13 14 17 16 18 15 10 12 11...

Page 94: ...D 10 18 10 21 20...

Page 96: ...D 10 18 12 23 22...

Page 98: ...D 10 18 14 25 24...

Page 100: ...D 10 18 16 26 27...

Page 102: ...D 10 18 18 28 29...

Page 104: ...D 10 18 20 30 31...

Page 106: ...D 10 18 22 32 33...

Page 108: ...D 10 18 24 34 35...

Page 110: ...D 10 18 26 36 37...

Page 112: ...D 10 18 28 38...

Page 114: ...D 10 18 30 39 40 41 42...

Page 116: ...D 10 18 32 44 43...

Page 118: ...D 10 18 34 45 46 47...

Page 120: ...D 10 18 36 47...

Page 124: ...D 10 18 40 90 91 92 94 93 95 96 96...

Page 126: ...D 10 18 42...

Page 127: ...D 24 18 1 D 24 18 Operating the display...

Page 151: ...D 24 18 25 Example...

Page 154: ...D 24 18 28...

Page 159: ...D 30 18 5 Control platform telescoping seat consoles 10 B A B 11 6 4 5 2 8 A 9 7 12...

Page 192: ...D 30 18 38...

Page 197: ...D 40 18 5 1 9 2 5 5 3 4 6 7 8...

Page 199: ...D 40 18 7 1 9 2 5 5 3 4 6 7 8...

Page 202: ...D 40 18 10 1 2 3 4 5 6...

Page 204: ...D 40 18 12 2 3 6 5 7 1...

Page 206: ...D 40 18 14 2 2 3 1 6 5 4...

Page 210: ...D 40 18 18 A 1 3 2 4...

Page 212: ...D 40 18 20 1 2 5 6 7 4 11 10 3 12 9 8...

Page 215: ...D 40 18 23 3 1 2...

Page 217: ...D 40 18 25 1 2 3...

Page 219: ...D 40 18 27 1 3 14 2 15 5 8 4 9 7 6 5 4 11 10 12 13 16...

Page 226: ...D 40 18 34...

Page 243: ...F 31 18 1 F 31 18 Maintenance conveyor 1 Maintenance conveyor...

Page 250: ...F 31 18 8...

Page 251: ...F 40 18 1 F 40 18Maintenance auger assembly 1 Maintenance auger assembly...

Page 275: ...F 60 18 1 F 60 18 Maintenance hydraulic system 1 Maintenance hydraulic system...

Page 291: ...F 70 18 1 F 70 18 Maintenance drive units 1 Maintenance drive units...

Page 303: ...F 82 18 1 F 82 18 Maintenance electrical system 1 Maintenance electrical system...

Page 318: ...F 82 18 16...

Page 326: ...F 90 18 8...

Page 327: ...F 100 1 F 100 Tests stopping 1 Tests checks cleaning stopping...

Page 338: ...F 100 12...

Page 340: ...F 110 18 2 2 6 6 1 7 3 4 5...

Page 346: ...F 110 18 8...

Page 347: ......

Page 348: ...www dynapac com...