D 30.18 30

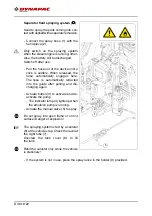

Screed eccentric adjustment

To pave thicker layers of material, if the

piston rods in the levelling cylinder are

operating close to their limit position and

if the desired paving thickness cannot be

reached, it is possible to alter the ap-

proach angle of the screed by adjusting

the eccentric.

- Pos. I:

Paving thickness up to

approx. 7 cm

- Pos. II

Paving thickness of

approx. 7 cm to

approx. 14 cm

- Pos. III

Paving thickness above

approx. 14 cm

- The spindle (1) is not adjusted.

- Unfasten locks (2) for eccentric adjustment.

- Swivel screed to the desired position using the lever (3), and engage the locking

knob again.

A

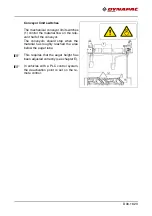

If the levelling unit is connected to a height controller, this has the function of balanc-

ing out any rapid rise in the screed position: The levelling cylinders are extended until

the correct height is reached.

A

The change in approach angle can only take place slowly and uniformly on both sides

at once during paving operation, and involves the use of eccentric adjustments. Fail-

ing this, any rapid response in the screed could easily cause waves to appear on the

road surface.

The setting process should therefore take place before work starts!

2

III

II

I

1

3

Summary of Contents for F1800C

Page 1: ...OPERATION MAINTENANCE Paver Finisher F1800C Type 910 03 1019 4812076575...

Page 2: ...www dynapac com...

Page 24: ...A 2...

Page 32: ...B 8 4 Safety devices 5 7 11 3 1 2 9 12 10 10 8 4 5 6 7...

Page 43: ...B 19 71 70 40 41 42 xxxxxxxxxxxxxxxxx 7 7 51 53 73...

Page 58: ...B 34...

Page 84: ...C 10 18 26...

Page 88: ...D 10 18 4 13 14 17 16 18 15 10 12 11...

Page 90: ...D 10 18 6 13 14 17 16 18 15 10 12 11...

Page 92: ...D 10 18 8 13 14 17 16 18 15 10 12 11...

Page 94: ...D 10 18 10 21 20...

Page 96: ...D 10 18 12 23 22...

Page 98: ...D 10 18 14 25 24...

Page 100: ...D 10 18 16 26 27...

Page 102: ...D 10 18 18 28 29...

Page 104: ...D 10 18 20 30 31...

Page 106: ...D 10 18 22 32 33...

Page 108: ...D 10 18 24 34 35...

Page 110: ...D 10 18 26 36 37...

Page 112: ...D 10 18 28 38...

Page 114: ...D 10 18 30 39 40 41 42...

Page 116: ...D 10 18 32 44 43...

Page 118: ...D 10 18 34 45 46 47...

Page 120: ...D 10 18 36 47...

Page 124: ...D 10 18 40 90 91 92 94 93 95 96 96...

Page 126: ...D 10 18 42...

Page 127: ...D 24 18 1 D 24 18 Operating the display...

Page 151: ...D 24 18 25 Example...

Page 154: ...D 24 18 28...

Page 159: ...D 30 18 5 Control platform telescoping seat consoles 10 B A B 11 6 4 5 2 8 A 9 7 12...

Page 192: ...D 30 18 38...

Page 197: ...D 40 18 5 1 9 2 5 5 3 4 6 7 8...

Page 199: ...D 40 18 7 1 9 2 5 5 3 4 6 7 8...

Page 202: ...D 40 18 10 1 2 3 4 5 6...

Page 204: ...D 40 18 12 2 3 6 5 7 1...

Page 206: ...D 40 18 14 2 2 3 1 6 5 4...

Page 210: ...D 40 18 18 A 1 3 2 4...

Page 212: ...D 40 18 20 1 2 5 6 7 4 11 10 3 12 9 8...

Page 215: ...D 40 18 23 3 1 2...

Page 217: ...D 40 18 25 1 2 3...

Page 219: ...D 40 18 27 1 3 14 2 15 5 8 4 9 7 6 5 4 11 10 12 13 16...

Page 226: ...D 40 18 34...

Page 243: ...F 31 18 1 F 31 18 Maintenance conveyor 1 Maintenance conveyor...

Page 250: ...F 31 18 8...

Page 251: ...F 40 18 1 F 40 18Maintenance auger assembly 1 Maintenance auger assembly...

Page 275: ...F 60 18 1 F 60 18 Maintenance hydraulic system 1 Maintenance hydraulic system...

Page 291: ...F 70 18 1 F 70 18 Maintenance drive units 1 Maintenance drive units...

Page 303: ...F 82 18 1 F 82 18 Maintenance electrical system 1 Maintenance electrical system...

Page 318: ...F 82 18 16...

Page 326: ...F 90 18 8...

Page 327: ...F 100 1 F 100 Tests stopping 1 Tests checks cleaning stopping...

Page 338: ...F 100 12...

Page 340: ...F 110 18 2 2 6 6 1 7 3 4 5...

Page 346: ...F 110 18 8...

Page 347: ......

Page 348: ...www dynapac com...