F 40.18 9

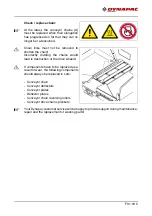

Outer auger bearing (4)

The grease nipples are located on

each side at the top of the outer

auger bearings.

These nipples must be lubricated at the

end of work to force out any bitumen res-

idues which may have entered and to

supply the bearings with fresh grease

when warm.

A

If the auger is extended, the outer rings

should be loosened slightly when initially

greasing the outer bearing points in or-

der to improve ventilation on greasing.

The outer rings must be properly se-

cured again after greasing.

A

New bearings must be filled with

60 strokes of grease using a grease gun.

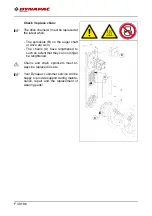

Mounting screws -

outer augur bearing

Check tightening (5)

m

Following the running-in period, the

tightening torques of the outer auger

bearing mounting screws must be

checked.

- Tighten to the following torques

if necessary:

- (F): 210 Nm

m

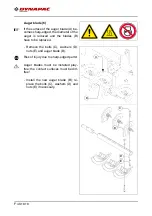

If the auger's working width is changed,

the tightening check must be repeated

after the running-in period!

6x

C

Summary of Contents for F1800C

Page 1: ...OPERATION MAINTENANCE Paver Finisher F1800C Type 910 03 1019 4812076575...

Page 2: ...www dynapac com...

Page 24: ...A 2...

Page 32: ...B 8 4 Safety devices 5 7 11 3 1 2 9 12 10 10 8 4 5 6 7...

Page 43: ...B 19 71 70 40 41 42 xxxxxxxxxxxxxxxxx 7 7 51 53 73...

Page 58: ...B 34...

Page 84: ...C 10 18 26...

Page 88: ...D 10 18 4 13 14 17 16 18 15 10 12 11...

Page 90: ...D 10 18 6 13 14 17 16 18 15 10 12 11...

Page 92: ...D 10 18 8 13 14 17 16 18 15 10 12 11...

Page 94: ...D 10 18 10 21 20...

Page 96: ...D 10 18 12 23 22...

Page 98: ...D 10 18 14 25 24...

Page 100: ...D 10 18 16 26 27...

Page 102: ...D 10 18 18 28 29...

Page 104: ...D 10 18 20 30 31...

Page 106: ...D 10 18 22 32 33...

Page 108: ...D 10 18 24 34 35...

Page 110: ...D 10 18 26 36 37...

Page 112: ...D 10 18 28 38...

Page 114: ...D 10 18 30 39 40 41 42...

Page 116: ...D 10 18 32 44 43...

Page 118: ...D 10 18 34 45 46 47...

Page 120: ...D 10 18 36 47...

Page 124: ...D 10 18 40 90 91 92 94 93 95 96 96...

Page 126: ...D 10 18 42...

Page 127: ...D 24 18 1 D 24 18 Operating the display...

Page 151: ...D 24 18 25 Example...

Page 154: ...D 24 18 28...

Page 159: ...D 30 18 5 Control platform telescoping seat consoles 10 B A B 11 6 4 5 2 8 A 9 7 12...

Page 192: ...D 30 18 38...

Page 197: ...D 40 18 5 1 9 2 5 5 3 4 6 7 8...

Page 199: ...D 40 18 7 1 9 2 5 5 3 4 6 7 8...

Page 202: ...D 40 18 10 1 2 3 4 5 6...

Page 204: ...D 40 18 12 2 3 6 5 7 1...

Page 206: ...D 40 18 14 2 2 3 1 6 5 4...

Page 210: ...D 40 18 18 A 1 3 2 4...

Page 212: ...D 40 18 20 1 2 5 6 7 4 11 10 3 12 9 8...

Page 215: ...D 40 18 23 3 1 2...

Page 217: ...D 40 18 25 1 2 3...

Page 219: ...D 40 18 27 1 3 14 2 15 5 8 4 9 7 6 5 4 11 10 12 13 16...

Page 226: ...D 40 18 34...

Page 243: ...F 31 18 1 F 31 18 Maintenance conveyor 1 Maintenance conveyor...

Page 250: ...F 31 18 8...

Page 251: ...F 40 18 1 F 40 18Maintenance auger assembly 1 Maintenance auger assembly...

Page 275: ...F 60 18 1 F 60 18 Maintenance hydraulic system 1 Maintenance hydraulic system...

Page 291: ...F 70 18 1 F 70 18 Maintenance drive units 1 Maintenance drive units...

Page 303: ...F 82 18 1 F 82 18 Maintenance electrical system 1 Maintenance electrical system...

Page 318: ...F 82 18 16...

Page 326: ...F 90 18 8...

Page 327: ...F 100 1 F 100 Tests stopping 1 Tests checks cleaning stopping...

Page 338: ...F 100 12...

Page 340: ...F 110 18 2 2 6 6 1 7 3 4 5...

Page 346: ...F 110 18 8...

Page 347: ......

Page 348: ...www dynapac com...