Machine head

41

Service Instructions 911-211 - 02.0 - 10/2016

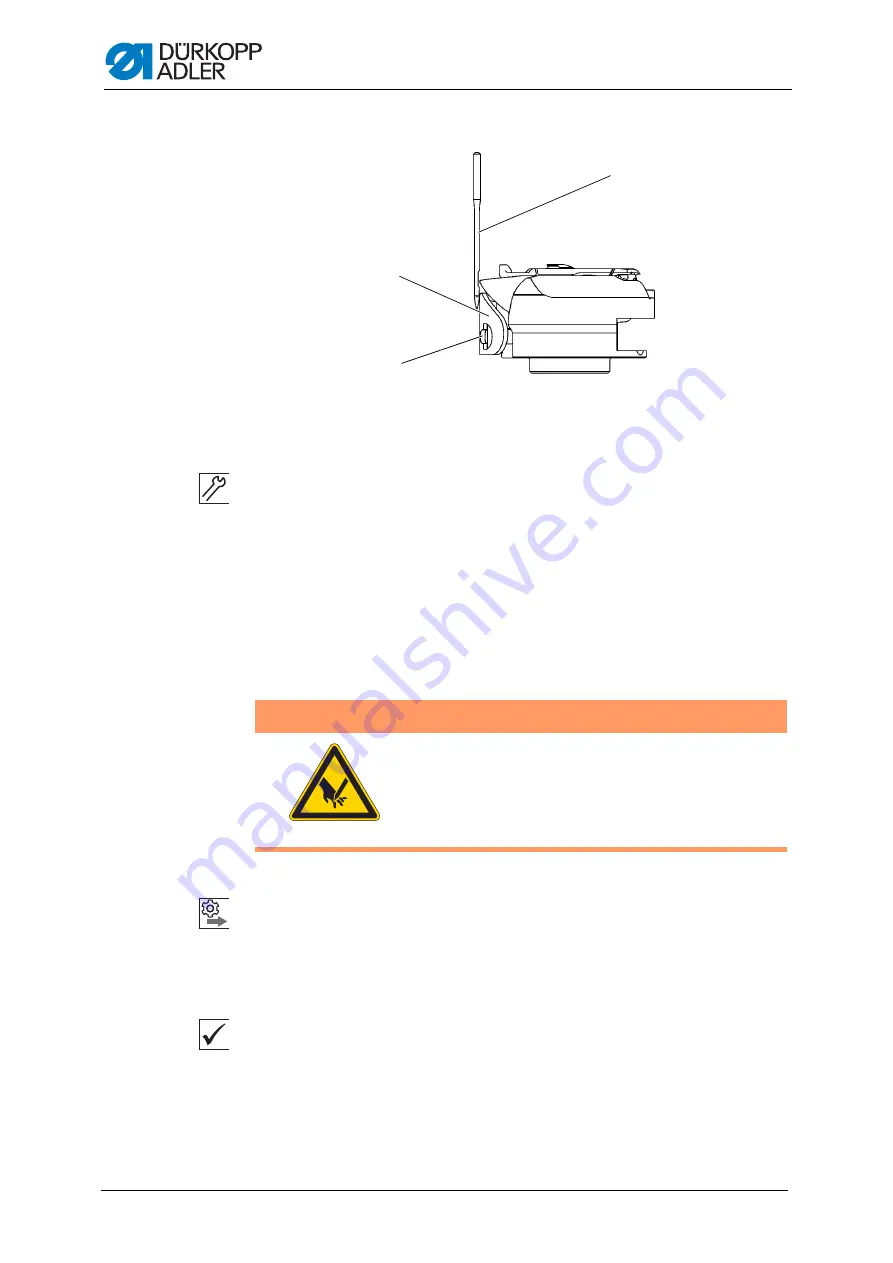

Fig. 28: Setting the needle guard

To set the needle guard:

1.

Press and turn the hand crank and check how far the needle guard (1)

pushes the needle (3) away.

2.

Turn the screw (2) such that the needle guard (1) just pushes the

needle (3) far away enough so that it is not touched by the hook tip:

• for pushing away more: Turn counterclockwise

• for pushing away less: Turn clockwise

4.4.5 Setting the needle guide

Order

First, check the following setting:

• A straight and undamaged needle has to be inserted (

Operating

Instructions

)

Proper setting

1.

Machine locked in place at position 1 (

The needle guard pushes the needle just enough away so that it can-

not be touched by the hook tip.

(1)

- Needle guard

(2)

- Screw

(3)

- Needle

③

①

②

WARNING

Risk of injury from sharp and moving parts!

Puncture or crushing possible.

Switch off the machine before you check and set

the needle guide.

Summary of Contents for 911-211

Page 1: ...Service Instructions 911 211...

Page 6: ...Table of Contents 5 Service Instructions 911 211 02 0 10 2016...

Page 10: ...About these instructions 9 Service Instructions 911 211 02 0 10 2016...

Page 90: ...Sewing unit 89 Service Instructions 911 211 02 0 10 2016...

Page 146: ...Creating programs with DA CAD 5000 145 Service Instructions 911 211 02 0 10 2016...

Page 158: ...Decommissioning 157 Service Instructions 911 211 02 0 10 2016...

Page 160: ...Disposal 159 Service Instructions 911 211 02 0 10 2016...

Page 170: ...Technical data 169 Service Instructions 911 211 02 0 10 2016...

Page 195: ...Appendix Service Instructions 911 211 02 0 10 2016 194...

Page 197: ...Appendix Service Instructions 911 211 02 0 10 2016 196 13 3 Pneumatic diagram...

Page 199: ......