Operation (CME)

5-7

“portable heat exchanger” is connected to the primary lines through the distribution

manifold. This will close the loop and allow circulation from the “supply” side to the

“return” side of the primary circulation line.

•

Open fully the “supply” isolation valves

figure 29

(15-2).

•

Open fully the “return” primary circulation line and valve

figure 29

(15-3).

•

Open the “return” isolation valve

figure 29

(15-4) to the “half open” position.

•

The “half open” position will ensure a slow introduction of cold heat transfer fluid

into the external circulation system and prevent a “cold-shock” of the system.

Note: Do not close this valve more than the ½ closed position. The restricted flow may

prevent the firing of the water heater.

•

Incrementally open the “return”

isolation valve

figure 29

(15-4) to

a fully open position.

•

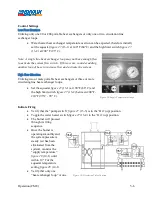

Monitor the “return temperature

before bypass” gauge

figure 30

(16-1) before fully connecting

more “heat exchanger loops” or

“portable heat exchangers”. This

gauge must show a noticeable

rise in temperature indicating the heat transfer fluid has made the full circuit. With

“heat exchanger loops”, this may take 10 minutes or more.

•

Repeat the previous step until all “portable heat exchangers” or “heat exchanger

loops” are connected and circulating.

Purging Air from the Fuel System

If the burner does not fire, the fuel system may have to be

purged of air.

•

Confirm that there is an adequate fuel supply.

•

Toggle the water heater switch

figure 31

(17-2) to

the “Off” downward position.

Figure 30-Return Temperature Before Bypass Gauge

Figure 31-Pump & Water Heater Switch

Summary of Contents for 600 GTS Series

Page 2: ......

Page 47: ...Appendix 9 3 Electrical Schematics Figure 56 600 GTS sub 40 Electrical Schematic...

Page 48: ...Appendix 9 4 Figure 57 600 GTS Electrical Schematic...

Page 49: ...Appendix 9 5 Figure 58 HR2250 Electrical Schematic...

Page 50: ...Appendix 9 6 Figure 59 Trailer Wiring Schematic...