7/ 22

5. COMPONENTS

5.1

FIXED DELIVERY PUMPING ELEMENTS

The pump has two fixed delivery standard pumping elements (200 cm^3/ min for each pumping element). A piston slides inside

the body of the pumping element coupled to the latter by a lapping process. The seal between the piston and the pumping body

is of a dry type, with no gasket provided between the two. The pumping element retention valve is of the tapered seal type. This

solution is able to guarantee an optimum seal for the system at high operating pressures (max. pressure of 400 bar). The

pumping elements are assembled on the manifold unit with a threaded attachment, which facilitates its assembly/ dismantling.

5.2

ENDLESS SCREW / WORM WHEEL UNIT

The pump has endless screw-worm wheel working kinematics with a transmission ratio of 1/40. The screw is made from special

steel with high mechanical resistance, which gives it optimum flexible rigidity. To guarantee high resistance to wear, the screw

has been subjected to Tenifer wear-resistant treatment. The screw is supported by oblique contact ball bearings, duly

preloaded, to reduce working clearance. The worm wheel is made of bronze alloy for gear systems, particularly suitable for

making the pump run quietly. The worm wheel shaft is made of special high resistance steel which gives the pump better

reliability and durability.

5.3

INVERTORS

CODE

DESCRIPTION

Series 0083420

Interchangeable electromagnetic inverter (mounted as standard on SUMO pump

Series 0083400

Electromagnetic inverter

Series 0083450

Electropneumatic inverter

SPARE PARTS

Code

Description

Current (A)

Power (W)

3150011

Electromagnet 24V DC

7

170

3150012

Electromagnet 110V AC 50/60 Hz

2

206

3150013

Electromagnet 230V AC 50/60 Hz

1

176

3133262

Seal kit

5.3.1

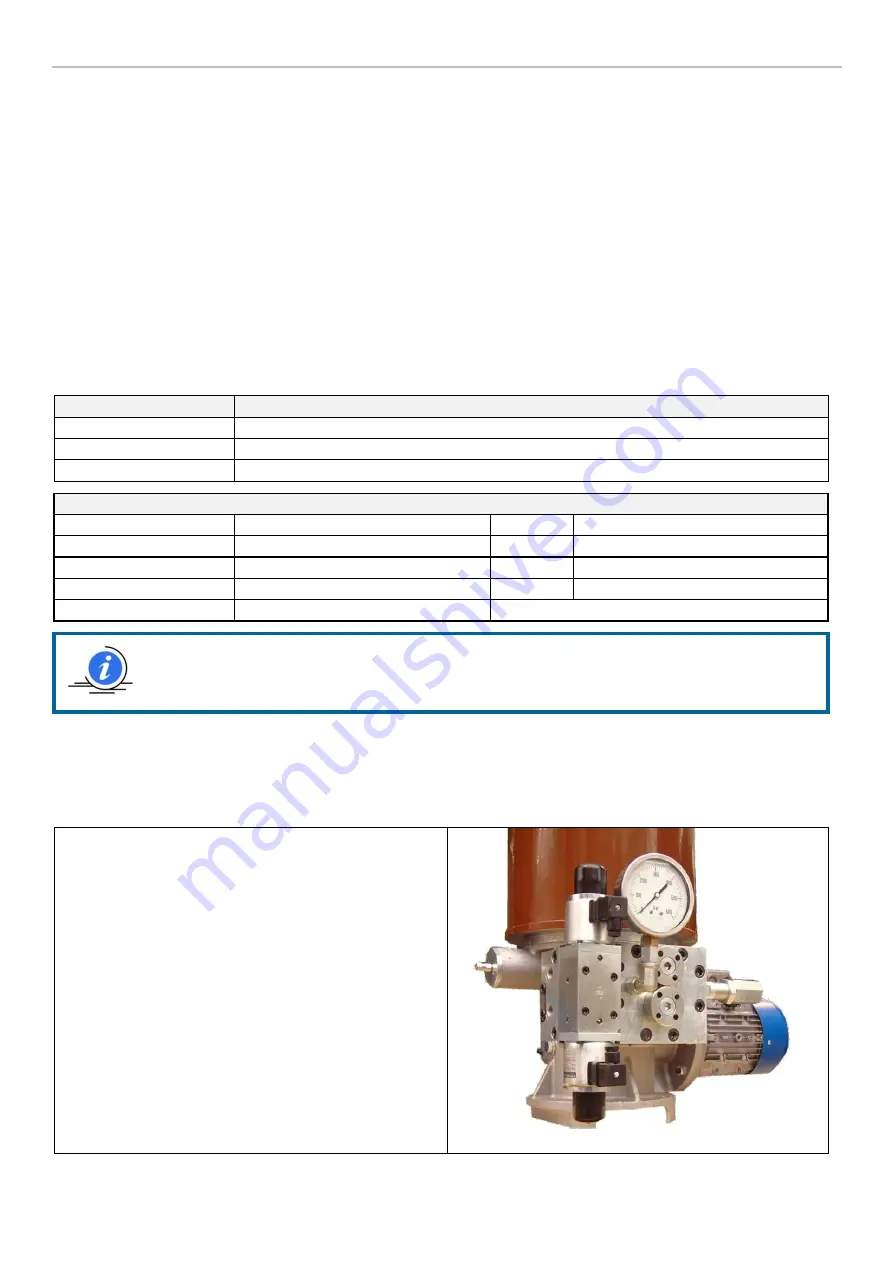

Interchangeable electromagnetic inverter (code 0083420 mounted on standard pump)

The standard pump is prepared for dual line function, with an electromagnetically controlled inverter being assembled as

standard. The inverter can be replaced if it is not working efficiently, without disconnecting the two line pipes (of an

interchangeable type). This is able to reduce maintenance times and the relating installation shutdown.

This version means that the inverter can be replaced without

disconnecting the line pipes. A solution of this type offers the

following advantages:

Ease of assembly and dismantling (only the 4 front Allen

screws need to be loosened and tightened);

Short replacement time;

Minimum installation shutdown time.

GENERAL NOTE FOR ALL INVERTERS

: It is advisable to plan a delay in the de-energizing of the

electromagnets from 2 ÷ 5 sec. to allow complete inversion in relation to the closing time of the pressure

gauge at the end of the line.

Photo 3