Tundra II Furnace Installation and Operation Manual

16

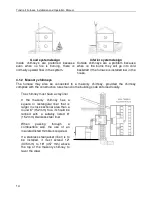

Proper installation

improper installation

o

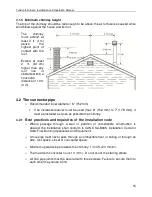

Maximum unsupported horizontal length: 3 feet (1 m);

o

Galvanized flue pipes must not be used because the coatings vaporize at high

temperatures and release dangerous gases;

o

Flue pipes must be at least 24 gauge in thickness;

o

The chimney connector must be in good condition;

o

Flue pipe joints should overlap 1 1/4". (30 mm);

o

Straight up installations needs to have either a connector where one end has no

fastener or a telescopic length;

o

Removal of the assembly for cleaning should not require that the furnace be

moved;

o

The male ends of the sections must be oriented towards the appliance so that

falling dust and condensation stay inside the pipe;

o

A straight flue pipe assembly offers the least restriction to gas flow and results in

stronger draft. Straight assemblies also need less maintenance because there

are no corners to collect creosote;

o

The use of 45° elbows is strongly recommended;

o

A 90° elbow = 5’ (152 cm), a 45° elbow = 2.5’ (76 cm);

o

Never use more than two 90° elbows.

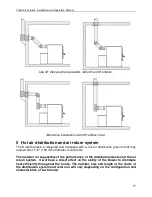

CAUSES

RESTRICTION

Summary of Contents for DF02001

Page 30: ...Tundra II Furnace Installation and Operation Manual 30 ...

Page 63: ...Tundra II Furnace Installation and Operation Manual 63 11 Exploded diagram and parts list ...

Page 64: ...Tundra II Furnace Installation and Operation Manual 64 ...

Page 65: ...Tundra II Furnace Installation and Operation Manual 65 ...

Page 66: ...Tundra II Furnace Installation and Operation Manual 66 ...

Page 67: ...Tundra II Furnace Installation and Operation Manual 67 ...

Page 73: ...Tundra II Furnace Installation and Operation Manual 73 12 2 1 Technical data Tundra II ...

Page 74: ...Tundra II Furnace Installation and Operation Manual 74 ...