SECTION 5

MAINTENANCE

Page 34

OM560C99/1E

DRESSTA

ELECTRICAL SYSTEM

WARNING! Never start the engine by connecting across the terminals on the

starter motor. Such staring is particularly dangerous with transmission in gear.

MAINTENANCE

Proper battery maintenance will assure maximum service. Following are a few simple rules:

1. Keep the battery cable terminals clean and tight.

2. Replace the worn, cracked, broken or corroded cables.

3. Keep the batteries fastened securely in the frame.

4. Maintain the proper electrolyte level when using regular batteries.

5. Maintain the batteries fully charged, particularly in winter.

NOTE:

Excessive tightening can warp or crack the battery case.

CLEANING THE BATTERIES

If the top of a battery is dirty, it may be cleaned with a brush dipped in ammonia or soda solution.

After the foaming stops, flush off the battery with clean water and unseal the vent plugs. Brighten

the terminal contact surfaces with steel wool or a stiff brush.

ATTACHING BOOSTER BATTERY

When the charge in the machine's batteries is to low to crank the engine, a booster battery can be

used to help start the engine.

WARNING! Always connect the ground cable last and disconnect the ground

cable first to avoid sparks near the battery. A spark could cause a battery

explosion and injury.

Connect the positive cable of the booster battery to the cranking motor and connect the negative

(ground) cable of the booster battery to the machine frame. Be sure the negative cable is 300 mm

or more away from the battery. The parking brake should be applied, and transmission lever locked

in neutral position.

ELECTROLYTE LEVEL

The electrolyte in each cell must be at the proper level (21 to 27 mm above the plates) at all times

to prevent battery failure. Check the level of the electrolyte. When the electrolyte is below this level,

pure distilled water must be added. Never use hydrant water or any water which has been in a

metal container. Acid or electrolyte must never be added except by a skilled battery man.

Under no circumstances add any special battery solutions or powders. It is especially important to

keep the battery at full charge for cold weather operation. Add distilled water to the battery in

freezing temperatures only when the engine is to operate for several hours, to thoroughly mix the

water and the electrolyte, or damage to the battery may occur.

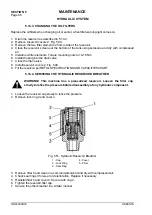

CHARGING FULLY DISCHARGED BATTERIES.

Check amount of charge of batteries:

100% of full charge

1.26 - 1.28 g/cm

3

75% of full charge

1.23 - 1.25 g/cm

3

50% of full charge

1.20 - 1.22 g/cm

3

Fully discharged

1.11 - 1.13 g/cm

3

When a machine is not in use for an extended period, the maintenance-free battery can become

discharged. For this reason, when a machine will not be used for over 30 days, it is recommended

that the negative ground terminal cable be disconnected. Prior to starting up a machine that has

been idle, always make a visual inspection of the battery and take an open circuit voltage test. A

reading of 1.23 g/cm

3

(75% of full charge) or less indicates a state of discharge.

Summary of Contents for 560C

Page 1: ...OM560C99 1E OPERATOR S MANUAL 560C SERIAL NUMBERS 15001 AND UP ...

Page 3: ......

Page 5: ......

Page 7: ......

Page 10: ...SECTION 1 INTRODUCTION ...

Page 12: ......

Page 16: ...SECTION 2 SAFETY PRECAUTIONS ...

Page 18: ......

Page 32: ...SECTION 3 MACHINE TRANSPORT AND STORAGE ...

Page 34: ......

Page 42: ...SECTION 4 OPERATING ...

Page 43: ......

Page 45: ......

Page 49: ...SECTION 4 OPERATING Page 6 OM560C99 1E DRESSTA UNIVERSAL SYMBOLS FOR INSTRUMENTS AND CONTROLS ...

Page 88: ...SECTION 5 MAINTENANCE ...

Page 141: ...SECTION 6 SPECIFICATIONS ...

Page 143: ......