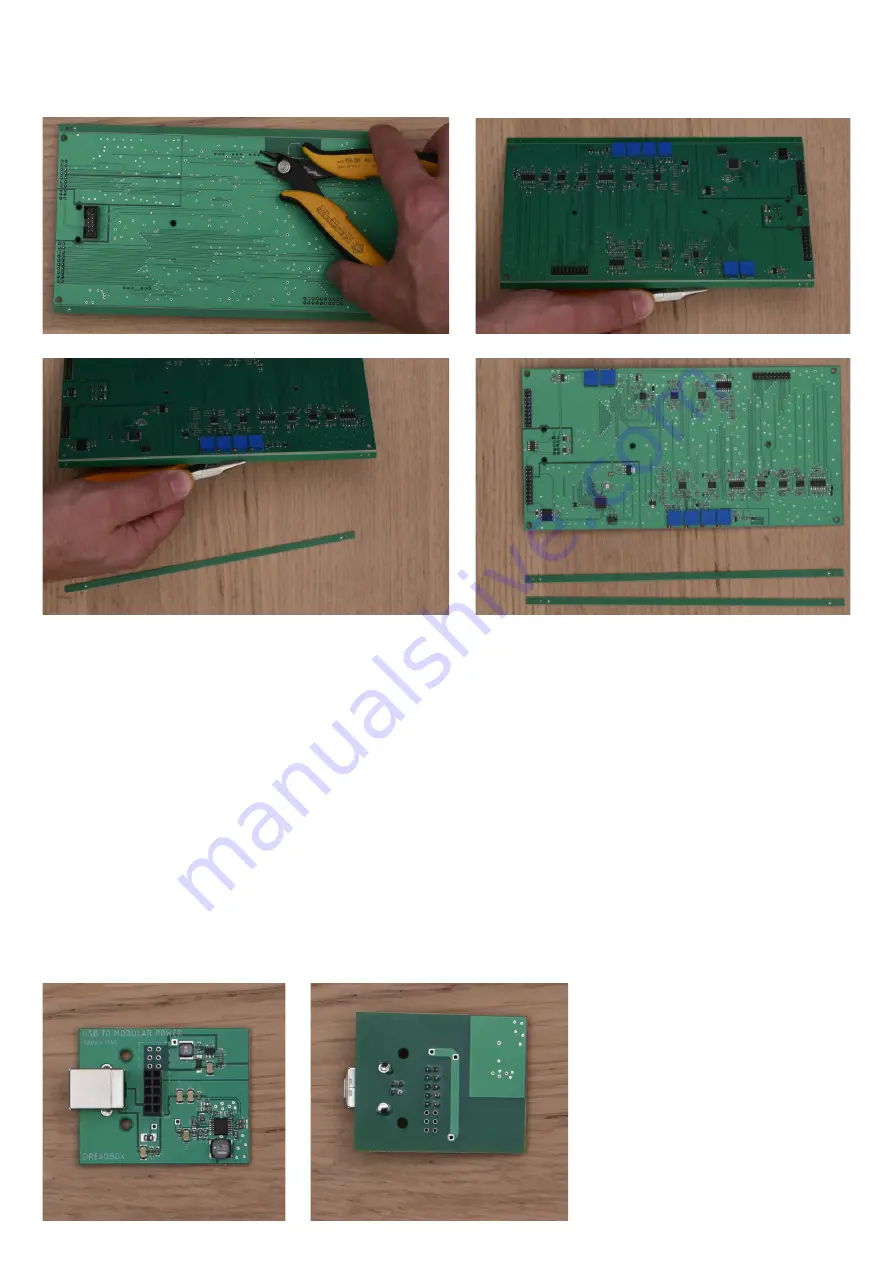

Then, cut the excess wires from the pre-assembled trimmers and remove the extra PCB from

the top and bottom side of the board.

1.5 Preparation of the power board

5

For this step you will need:

- The 0.7 solder wire + a soldering iron

- The USB jack

- The 10pin female header

Solder the USB jack and the header, as shown in the pictures.

You can also use this board as a generic modular power supply. Max supplied current is

200mA@+12V and 80mA@-12V. In order to do this, you need to solder a 16pin male

ribbon header

(not included in the kit)

, instead of the 10pin female.

Pin "1" is marked with a small circle at the bottom right.