28

ED100LE

02-2021

DL4616-001

dormakaba ED100LE operator – Fine cover

Installation Instructions

Chapter 9

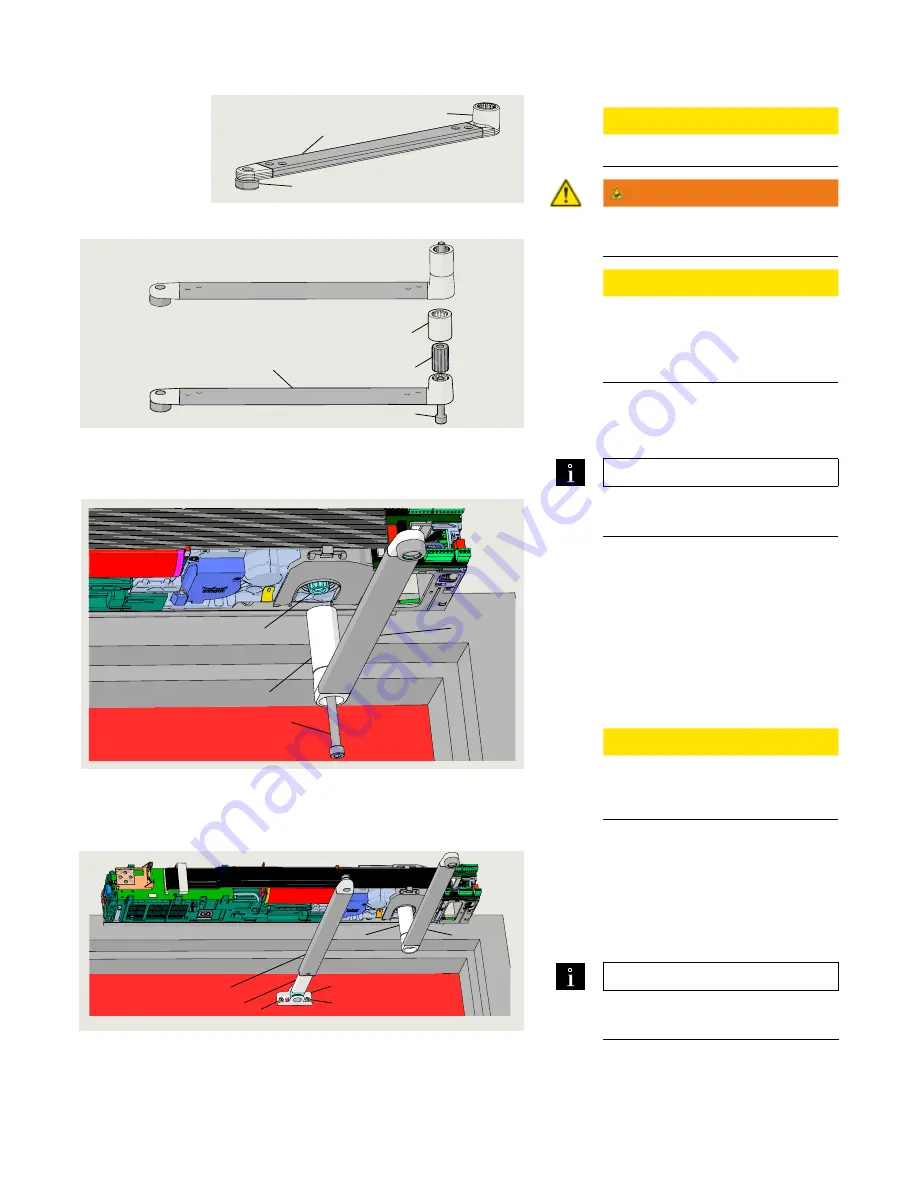

Fig. 9.2.5 Push arm assemblies for installation

9.2.2 Attach drive arm to operator.

CAUTION

Door must be fully closed!

WARNING

Use caution when working in

proximity of door and push arm!.

CAUTION

ED operator axle zero position.

In order to mount the drive arm in

the correct position, the axle must

be brought to the zero position.

1. Set ED100LE operator spring preload to

approximately ten clockwise rotations.

• Axle rotates to the zero position.

TIPS AND RECOMMENDATIONS

Reference Para. Chapter 12, Set

operator spring tension.

2. Insert axle extension into drive arm.

• Reference Chapter 7 for installation

templates.

3. Move arm to ED100LE, inserting arm

into axle extension sleeve at a 90⁰ angle

to operator (Fig. 9.2.5).

4. Insert M8 SHCS through drive arm and

axle extension. Thread SHCS into

ED100LE spindle and tighten.

CAUTION

Use torque wrench with hex key

socket to tighten SHCS to

17 ft-lb [23 Nm]

9.2.3 Drill two holes in door for adjustment

arm shoe.

Installation templates (Chapter 7)

document location of shoe on door.

1. Drill two holes in door for adjustment

arm shoe.

• Fastener type based on door material.

TIPS AND RECOMMENDATIONS

Reference Chapter 2 for arm

fasteners.

9.2.4 Secure adjustment arm assembly to

door.

1. Fasten adjustment arm assembly to

door (Fig. 9.2.6).

1

Drive arm

11

Spindle

12

Axle extension sleeve

14

M8 x __ SHCS

Fig. 9.2.6 Arm assemblies attached to door and ED100LE

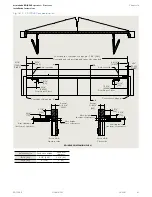

Fig. 9.2.3 Drive arm

1

Drive arm

2

Socket

3

Arm axle sleeve

1

2

3

Fig. 9.2.4 Drive arm extension installation

1

Drive arm

12

Axle extension sleeve

13

Axle extension

14

M8 x ___ SHCS

1

12

13

14

1

Drive arm

4

Adjustment arm

11 1/4"[285]

5

Adjustment arm

tube 12 1/4" [311]

6

Shoe

7

Fastener

9

Adjustment arm,

17 3/4" [450]

10

Adjustment arm

tube, 17 3/4" [450]

12

Axle extension sleeve

5,10

4,9

6

1

7

7

12

1

14

12

11