Maintenance

- 89 -

Wet the fixing bolts with engine oil,

semitighten them with hand, tighten

them to the specified torque using a

torque wrench as follows.

<Tightening order>

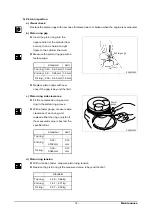

(1) Second stage : Temporary bolt screwing about 1 ~ 2 threads

(2) Second stage : Tighten the bolt using a torque wrench to a torque of 4 kgf·m.

(3) Third stage

: Mark the bolt head and its contacting surface.

(4) Fourth stage : Further tighten the bolt using a torque wrench until the marking made in fourth

stage is turned another 60°.

When the connecting rod bearing cap

bolts are tightened, check the

connecting rod end play to the right and

left with hand.

If no end play is found, remove and

reinstall or replace the connecting rod

bearing cap.

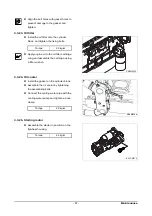

3.3.17. Oil pump and oil pipe

Install a dowel pin in the No.7 bearing

cap, then assemble the oil pump by

tapping lightly with urethane hammer.

Tighten the assembling bolts with

specified torque.

Assemble the oil suction pipe with the

delivery pipe to oil pump by the bolts.

EGL0818006

60°

Torque

1st Step

4 kg

•

m

2nd Step

60°

EAMD094I

EB5M3017

Torque

4.4 kg

•

m

Summary of Contents for GL08K

Page 1: ...950106 050004EN GL08K GAS VEHICLE ENGINE Operation Maintenance Manual ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 151: ...Maintenance 145 7 Vehicle wiring harness EH3M5012 Truck engine Bus engine ...

Page 193: ...Appendix 187 Engine Assembly Bus EJ3OM012 ...

Page 194: ...Appendix 188 Engine Assembly Truck EJ3OM013 ...

Page 195: ...Special Tool List 950106 080002 ...

Page 196: ......