Maintenance

- 61 -

3.2. Inspection and Measurement on Major Parts

3.2.1. Cylinder block

Clean the cylinder block thoroughly, and check for any crack or damage.

If there is any crack or severe damage, replace it and if there is minor one, correct it.

Check for any clogging or corrosion in the oil passage and water passage.

Carry out a leakage test for any crack or air leaking. (Hydraulic test)

Plug each cylinder block’s water and oil discharge ports, and apply the air pressure of about 4 kg/cm

2

to intake port and soak it in water for about 1 minute to check if there is any leakage. (Water

temperature : 70 °C)

3.2.2. Cylinder head

1) Cylinder head assembly & disassembly

a) Disassemble the cylinder assembly, and put it on the shelf for assembly or clean lathe.

CAUTION :

Prevent any damage to gasket's contact surface of the cylinder head.

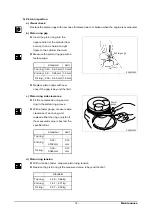

b) Disassemble the cotter pin, spring,

spring seat pushing valve spring by a

special tool.

c) Pull out the intake and exhaust

valves.

d) The disassembled parts are kept laid

in turn.

e) Disassemble the valve stem seal.

f) By means of the special tool, punch,

pull out a valve guide.

Compress

the spring

EA0M4007

EA5M3018

Summary of Contents for GL08K

Page 1: ...950106 050004EN GL08K GAS VEHICLE ENGINE Operation Maintenance Manual ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 151: ...Maintenance 145 7 Vehicle wiring harness EH3M5012 Truck engine Bus engine ...

Page 193: ...Appendix 187 Engine Assembly Bus EJ3OM012 ...

Page 194: ...Appendix 188 Engine Assembly Truck EJ3OM013 ...

Page 195: ...Special Tool List 950106 080002 ...

Page 196: ......