Maintenance

- 84 -

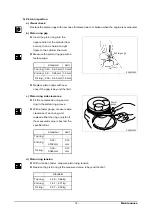

Install a guide bar into a bolt hole on the

crank shaft, and lift the flywheel to align the

dowel pin with the pin hole on the flywheel

for temporary assembly operation.

Coat the adhesive (#271 Loctite) over the

assembling bolts and install bolts in the

remaining holes. After that take out the

guide bar, then install a bolt in the hole

where the guide bar had been inserted.

According to the order of tightening

tighten the fixing bolts using a torque

wrench in a diagonal sequence to

specified torque.

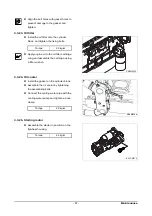

3.3.10. Magnetic pick-up sensor

Move the lock nut to hexagonal side of

sensor completely.

Rotate (Clockwise) the pick-up sensor

on flywheel housing, until the end of it

reach on flywheel ring gear.

Then rotate (Counter clockwise) the

pickup sensor for 270° (gap 1.0 mm) and

fix lock nut.

Tolerance limit is 27°. (gap ± 0.1 mm)

EAMD081I

Torque

18 kg

•

m

1

5

4

3

6

2

EDM2073I

EPM2030I

Lock nut

Ring gear

M16 x 1.5

EPM2031I

270

27

27

Flywheel

Housing

Tolerance

limit

Summary of Contents for GL08K

Page 1: ...950106 050004EN GL08K GAS VEHICLE ENGINE Operation Maintenance Manual ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 151: ...Maintenance 145 7 Vehicle wiring harness EH3M5012 Truck engine Bus engine ...

Page 193: ...Appendix 187 Engine Assembly Bus EJ3OM012 ...

Page 194: ...Appendix 188 Engine Assembly Truck EJ3OM013 ...

Page 195: ...Special Tool List 950106 080002 ...

Page 196: ......