Maintenance

- 71 -

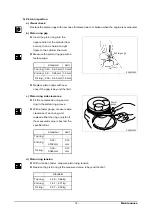

b) Wear measuring

With an outside micrometer

measure the diameter of the

crankshaft journals and pins in the

directions as shown, and compare

the measured values to determine

the amount of wear.

If the amount of wear is beyond the

limit, have the crankshaft ground

and install undersize bearings.

However, if the amount of wear is

within the limit, you can correct the

wear using an oil stone or oiled

grinding paper of fine grain size.

(Be sure to use grinding paper

which has been immersed in oil.)

In case that pin's wear is more

than the limit value, grind the

crankshaft journal and crank pin,

and use the undersized bearings.

CAUTION :

Be sure to use grinding paper which

has been immersed in oil.

<Undersize bearings available>

- Standard

- 0.25 (Inside diameter is 0.25 mm lesser than the standard size.)

- 0.50 (Inside diameter is 0.50 mm lesser than the standard size.)

- 0.75 (Inside diameter is 0.75 mm lesser than the standard size.)

- 1.00 (Inside diameter is 1.00 mm lesser than the standard size.)

There are four sizes of under-size bearings for main bearings and two sizes for connecting rod

bearings. The crankshaft can be re-machined to fit in these under-size bearings.

EAMD057I

B

B

B

A

A

B

EFM2047I

Standard

Limit

Journal

diameter

83.966 ~

83.988 mm

83.466

mm

Pin

diameter

70.971 ~

70.990 mm

69.971

mm

" R "

" R "

" R "

" R "

EFM2048I

" R "

Normal

Poor

Poor

Summary of Contents for GL08K

Page 1: ...950106 050004EN GL08K GAS VEHICLE ENGINE Operation Maintenance Manual ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 151: ...Maintenance 145 7 Vehicle wiring harness EH3M5012 Truck engine Bus engine ...

Page 193: ...Appendix 187 Engine Assembly Bus EJ3OM012 ...

Page 194: ...Appendix 188 Engine Assembly Truck EJ3OM013 ...

Page 195: ...Special Tool List 950106 080002 ...

Page 196: ......