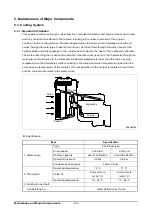

Maintenance of Major Components

- 166 -

5.3.3. Cleaning filter elements

By compressed air

(wear goggles)

- For the purpose, the air gun should be

fitted with a nozzle extension which is

bent 90° at the discharge end and

which is long enough to reach down

inside to the bottom of the element.

- Moving the air gun up and down, blow

out the element from the inside

(maximum 500kPa - 5 bar) until no

more dust comes out of the filter pleats.

By washing

- Before washing, the element should

be precleaned by means of

compressed air, as described above.

- Then allow the element to soak in

lukewarm washing solvent for 10

minutes, and then move it to and for in

the solvent for about 5 minutes.

- Rinse thoroughly in clean water,

shake out and allow drying at room

temperature. The cartridge must be

dry before it is reinstalled.

- Never use steam sprayers, petrol

(gasoline), alkalis or hot liquids etc. to

clean the filter elements.

Knocking out dirt by hand

- In emergencies, when no compressed air or cleaning agent is available, it is possible to clean the

filter cartridge provisionally by hitting the end disk of the cartridge with the ball of one's thumb.

- Under no circumstances should the element be hit with a hard object or knocked against a hard

surface to loosen dirt deposits.

Checking the filter cartridge

- Before reinstalling the cartridge, it must

be checked for damage e.g. to the paper

pleats and rubber gaskets, or for bulges

and dents etc. in the metal jacket.

- Cracks and holes in the paper pleating

can be established by inspecting the

cartridge with a flashlight.

- Damaged cartridges should not be

reused under any circumstances. In

cases of doubt, discard the cartridge

and install a new one.

EA6O5014

EA6O5015

EA6O5016

Summary of Contents for GL08K

Page 1: ...950106 050004EN GL08K GAS VEHICLE ENGINE Operation Maintenance Manual ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 151: ...Maintenance 145 7 Vehicle wiring harness EH3M5012 Truck engine Bus engine ...

Page 193: ...Appendix 187 Engine Assembly Bus EJ3OM012 ...

Page 194: ...Appendix 188 Engine Assembly Truck EJ3OM013 ...

Page 195: ...Special Tool List 950106 080002 ...

Page 196: ......