68

G60, G80, G100, G150, G200-SIIIA OM Manual

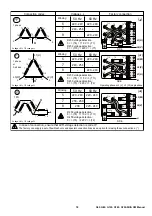

SPECIFICATIONS (CONT’D)

Metric Bolt and Screw Torque Values

a

“Lubricated” means coated with a lubricant such as engine oil, fasteners with phosphate and oil coatings, or M20 and

larger fasteners with JDM F13C, F13F or F13J zinc flake coating.

b

“Dry” means plain or zinc plated without any lubrication, or M6 to M18 fasteners with JDM F13B, F13E or F13H zinc

flake coating.

Bolt or

Screw Size

Class 4.8

Class 8.8 or 9.8

Class 10.9

Class 12.9

Lubricated

a

Dry

b

Lubricated

a

Dry

b

Lubricated

a

Dry

b

Lubricated

a

Dry

b

N·m lb.-in. N·m lb.-in. N·m lb.-in. N·m lb.-in. N·m lb.-in. N·m lb.-in. N·m lb.-in. N·m lb.-in.

M6

4.7

42

6

53

8.9

79

11.3

100

13

115

16.5

146

15.5

137

19.5

172

N·m lb.-ft. N·m lb.-ft. N·m lb.-ft. N·m lb.-ft.

M8

11.5

102

14.5

128

22

194

27.5

243

32

23.5

40

29.5

37

27.5

47

35

N·m lb.-ft. N·m lb.-ft. N·m lb.-ft.

M10

23

204

29

21

43

32

55

40

63

46

80

59

75

55

95

70

N·m lb.-ft.

M12

40

29.5

50

37

75

55

95

70

110

80

140

105

130

95

165

120

M14

63

46

80

59

120

88

150

110

175

130

220

165

205

150

260

190

M16

100

74

125

92

190

140

240

175

275

200

350

255

320

235

400

300

M18

135

100

170

125

265

195

330

245

375

275

475

350

440

325

560

410

M20

190

140

245

180

375

275

475

350

530

390

675

500

625

460

790

580

M22

265

195

330

245

510

375

650

480

725

535

920

680

850

625

1080

800

M24

330

245

425

315

650

480

820

600

920

680

1150

850

1080

800

1350 1000

M27

490

360

625

460

950

700

1200

885

1350 1000 1700 1250 1580 1160 2000 1475

M30

660

490

850

625

1290

950

1630 1200 1850 1350 2300 1700 2140 1580 2700 2000

M33

900

665

1150

850

1750 1300 2200 1625 2500 1850 3150 2325 2900 2150 3700 2730

M36

1150

850

1450 1075 2250 1650 2850 2100 3200 2350 4050 3000 3750 2770 4750 3500

Torque values listed are for general use only, based on

the strength of the bolt or screw. DO NOT use these

values if a different torque value or tightening procedure is

given for a specific application. For stainless steel

fasteners or for nuts on U-bolts, see the tightening

instructions for the specific application. Tighten plastic

insert or crimped steel type lock nuts by turning the nut to

the dry torque shown in the chart, unless different

instructions are given for the specific application.

Shear bolts are designed to fail under predetermined

loads. Always replace shear bolts with identical property

class. Replace fasteners with the same or higher property

class. If higher property class fasteners are used, tighten

these to the strength of the original. Make sure fastener

threads are clean and that you properly start thread

engagement. When possible, lubricate plain or zinc plated

fasteners other than lock nuts, wheel bolts or wheel nuts,

unless different instructions are given for the specific

application.

Summary of Contents for G06030001

Page 2: ......

Page 4: ...4 G60 G80 G100 G150 G200 SIIIA OM Manual ...

Page 8: ...8 G60 G80 G100 G150 G200 SIIIA OM Manual ...

Page 9: ...9 G60 G80 G100 G150 G200 SIIIA OM Manual ...

Page 10: ...10 G60 G80 G100 G150 G200 SIIIA OM Manual ...

Page 14: ...14 G60 G80 G100 G150 G200 SIIIA OM Manual ...

Page 89: ......

Page 90: ......