MAN05MGO5

INSTRUCTIONS JIB CRANE SERIES GBA - GBP

7

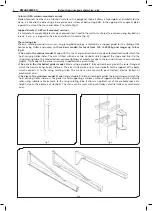

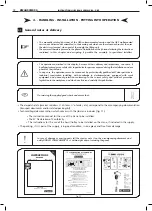

4HECONCEPTIONANDCONSTRUCTION

• The manually rotated

jib cranes

in the GBA column-mounted version and the GBP wall-mounted version are

designed according to the conception of the modular components which put together in relation to commercial

needs, as well as the standard models always available from the warehouse, allow the rapid economical realisation

of numerous normalised and special executions.

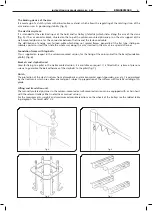

•Thebase,column,bracketandarmscomponents,thankstotheirextremecompactnessareassemblabletogether,

so as to guarantee the maximum use of the hook run and, thanks to the minimal side clearance allow an optimal

use of the area in which the jib crane operates.

• The construction uses the most advanced technology which is based on production processes of high

industrialization and allows the realization, using economies of scale, of totally reliable and technically innovative

machines. The high level of quality is guaranteed and controlled by the company quality system according to the

UNI EN ISO 9001:2008 standard.

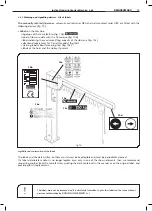

2.2.1 Safety reference list

In the planning and construction of the manually rotated jib cranes, column-mounted series GBA and wall-mounted

series GBP the following standards and principal technical regulations have been taken into account:

•ENISO12100/2010“Safetyofthemachinery”

•ENISO13849-1/2008“Generalprinciplesfordesign”

•EN60204-32/2009“Safetyofmachineryelectricalequipmentofmachines”

•EN60529/92“Degreesofprotectionprovidedbyenclosures(IPcode)”

•ISO4301-1/86“Liftingequipmentclassification”

•FEM1.001/98“Rulesforthedesignofhoistingappliances”

•FEM9.683/95“Selectionofliftingandtravelmotors”

•FEM9.755/93“Measuresforachievingsafeworkingperiodsforserialhoistsunits(S.W.P.)”

•FEM9.941/95“Graphicalsymbolsforcontroldevices”

2.2.2 Protection and insulation of electrical parts

•Cables:CEI20/22II-Maximuminsulationvoltage450/750V

2.2.3 Electrical power supply

•Thejibcranesaredesignedtobepoweredwithalternatingelectriccurrentwithmaximumthree-phase

voltage of 600 V

2.2.4 Environment conditions of use

•Temperatureofuse:minimum–10°C;m40°C

•Maximumrelativehumidity:80%

•Themachinemustbeplacedinawell-ventilatedplace,freefromcorrosivevapours(acidvapours,saline

clouds, etc)

2.2

Technical information and service conditions

•Itisforbiddentousethemachineinanexplosiveenvironmentoronewhichispotentiallyso,orwhere

the use of flameproof equipment is prescribed.

•Itisnecessarytoallocatesufficientworkingspacetoensurethesafetyoftheoperatorandofthe

maintenance staff.

KMAN05MG05

97

88