MAN05MGO5

INSTRUCTIONS JIB CRANE SERIES GBA - GBP

9

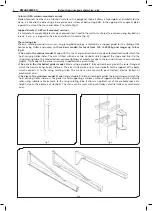

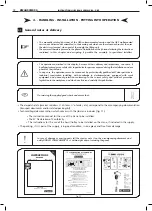

2.2.7 Characteristics and technical data - Weights - Reactions on constraints

#6ERSIONCHANNELPROFILEVERSION

Wall-mounted jib crane – Rotation 270°

$IMENSIONS,-AND.FORWALLMOUNTEDJIBCRANES3EECORRESPONDINGHEIGHTSRELATIVETOCOLUMNMOUNTEDJIBCRANES

Column-mounted jib crane – Rotation 300°

,IFTING

capacity

4 4056 A R

5 5056 A R

6 6056 B S

7 7056 B S

C01A40 170

552

644

200

594

150

15

74

C01A50 170

552

644

200

594

150

15

87

C01B60 170

552

644

200

594

150

15

100

C01B70 170

552

644

200

594

150

15

113

3 5 C30R40 2496 228

34

140

585

12

127 18.2

3 5 C30R50 2496 228

34

140

645

12

140 18.2

3 5 C30S60 2496 274

34

140

705

12

175 22.8

3 5 C30S70 2496 274

34

140

765

12

188 22.8

63

2

2056 A R

3

3056 A R

4

4056 B S

5

5056 B S

6

6066 C T

7

7066 C T

C01A20 170

552

644

200

594

150

15

48

C01A30 170

552

644

200

594

150

15

61

C01B40 170

552

644

200

594

150

15

74

C01B50 170

552

644

200

594

150

15

87

C02C60 210

820

930

250

870

190

22

135

C02C70 210

820

930

250

870

190

22

150

3 5 C30R20 2496 228

34

140

525

12

101 18.2

3 5 C30R30 2496 228

34

140

585

12

114 18.2

3 5 C30S40 2496 274

34

140

585

12

149 22.8

3 5 C30S50 2496 274

34

140

645

12

162 22.8

3.5 5.5 C35T60 2738 323

34

140

785

17

260 35

3.5 5.5 C35T70 2738 323

34

140

845

17

275 35

125

2

2056 B S

3

3056 B S

4

4066 C T

5

5066 C T

6

6066 D U

7

7066 D U

250

C01B20 170

552

644

200

594

150

15

48

C01B30 170

552

644

200

594

150

15

61

C02C40 210

820

930

250

870

190

22

105

C02C50 210

820

930

250

870

190

22

120

C02D60 210

820

930

250

870

190

22

202

C02D70 210

820

930

250

870

190

22

228

3 5 C30S20 2496 274

34

140

525

12

123 22.8

3 5 C30S30 2496 274

34

140

585

12

136 22.8

3.5 5.5 C35T40 2738 323

34

140

665

17

230 35

3.5 5.5 C35T50 2738 323

34

140

725

17

245 35

3.5 5.5 C35U60 2738 386

43

156

820

17

376 43.5

3.5 5.5 C35U70 2738 386

43

156

880

17

402 43.5

2

2066 C T

3

3066 C T

4

4066 D U

5

5066 D U

6

6076 E V

7

7076 E V

500

C02C20 210

820

930

250

870

190

22

75

C02C30 210

820

930

250

870

190

22

90

C02D40 210

820

930

250

870

190

22

113

C02D50 210

820

930

250

870

190

22

129

C03E60 255

1100

1240

300

1160

220

34

270

C03E70 255

1100

1240

300

1160

220

34

300

3.5 5.5 C35T20 2738 323

34

265

730

17

200 35

3.5 5.5 C35T30 2738 323

34

265

790

17

215 35

3.5 5.5 C35U40 2738 386

34

265

820

17

287 43.5

3.5 5.5 C35U50 2738 386

34

265

880

17

303 43.5

4 6 C40V60 2980 443

43

156

880

20

567 64

4 6 C40V70 2980 443

43

156

940

20

597 64

2

2066 D U

3

3066 D U

4

4076 E V

5

5076 E V

6

6076 F Z

7

7076 F Z

1000

C02D20 210

820

930

250

870

190

22

93

C02D30 210

820

930

250

870

190

22

163

C03E40 255

1100

1240

300

1160

220

34

212

C03E50 255

1100

1240

300

1160

220

34

241

C03F60 255

1100

1240

300

1160

220

34

298

C03F70 255

1100

1240

300

1160

220

34

331

3.5 5.5 C35U20 2738 386

60

306

790

17

267 43.5

3.5 5.5 C35U30 2738 386

60

306

850

17

337 43.5

4 6 C40V40 2980 443

60

306

910

20

509 64

4 6 C40V50 2980 443

60

306

970

20

538 64

4 6 C40Z60 2980 513

60

306

1100

20

680 75.2

4 6 C40Z70 2980 513

60

306

1160

20

713 75.2

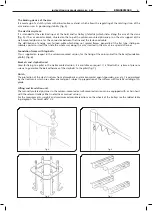

kg m mm

A

Codice

tipo

Overrall dimensions (mm)

GBP series wall-mounted jib cranes - C version

weight

of

crane

B

C

D

E

F

Ø

kg

4RUE

,ENGHT

Nominal

Arm

S

Type

Overrall dimensions (mm)

Weight

GBA series column-mounted jib crane – C version

Column

by

m

Crane

Under

beam

h

G

,

M

N

6

kg

kg

Size

of

jib

crane

Bracket

Column

H

m

T

otal

Height

base

max.

KMAN05MG05

LIFTING CAP

ACITY

ARM

S

SIZE OF

JIB CRANE

TROLLEY TYPE

GBP SERIES WALL-MOUNTED JIB CRANES - C VERSION

GBA SERIES COLUMN-MOUNTED CRANE - VERSION C

ARM

ARM

C/W

COVER

TYPE

OVERALL DIMENSIONS (mm)

WEIGHT JIB CRANE

HEIGHT

TYPE

OVERALL DIMENSIONS (mm)

WEIGHT

BRA

CKET

COLUMN

A

B

C

D

E

F

Ø

H

m

UNDER

BEAM

JIB

CRANE

COLUMN

BY m

kg

m

mm

kg

BASE MAX.

h

G

L

M

N

Δ

kg

kg

63

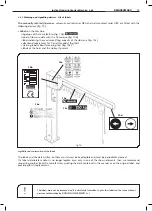

4 4056 A R CCP C01A40 170 552 644 200 594 150

15

74

3

5

C30R40 2496 228

34 140 585 12

127

18.2

5 5056 A R CCP C01A50 170 552 644 200 594 150

15

87

3

5

C30R50 2496 228

34 140 645 12

140

18.2

6 6056 B S CCP C01B60 170 552 644 200 594 150

15 100

3

5

C30S60 2496 274

34 140 705 12

175

22.8

7 7056 B S CCP C01B70 170 552 644 200 594 150

15 113

3

5

C30S70 2496 274

34 140 765 12

188

22.8

125

2 2056 A R CCP C01A20 170 552 644 200 594 150

15

48

3

5

C30R20 2496 228

34 140 525 12

101

18.2

3 3056 A R CCP C01A30 170 552 644 200 594 150

15

61

3

5

C30R30 2496 228

34 140 585 12

114

18.2

4 4056 B S CCP C01B40 170 552 644 200 594 150

15

74

3

5

C30S40 2496 274

34 140 585 12

149

22.8

5 5056 B S CCP C01B50 170 552 644 200 594 150

15

87

3

5

C30S50 2496 274

34 140 645 12

162

22.8

6 6066 C T CCP C02C60 210 820 930 250 870 190

22 135

3.5

5.5 C35T60 2738 323

34 140 785 17

260

35

7 7066 C T CCP C02C70 210 820 930 250 870 190

22 150

3.5

5.5 C35T70 2738 323

34 140 845 17

275

35

250

2 2056 B S CCP C01B20 170 552 644 200 594 150

15

48

3

5

C30S20 2496 274

34 140 525 12

123

22.8

3 3056 B S CCP C01B30 170 552 644 200 594 150

15

61

3

5

C30S30 2496 274

34 140 585 12

136

22.8

4 4066 C T CCP C02C40 210 820 930 250 870 190

22 105

3.5

5.5 C35T40 2738 323

34 140 665 17

230

35

5 5066 C T CCP C02C50 210 820 930 250 870 190

22 120

3.5

5.5 C35T50 2738 323

34 140 725 17

245

35

6 6066 D U CCG C02D60 210 820 930 250 870 190

22 202

3.5

5.5 C35U60 2738 386

43 156 820 17

376

43.5

7 7066 D U CCG C02D70 210 820 930 250 870 190

22 228

3.5

5.5 C35U70 2738 386

43 156 880 17

402

43.5

500

2 2066 C T CCPD C02C20 210 820 930 250 870 190

22

75

3.5

5.5 C35T20 2738 323

34 265 730 17

200

35

3 3066 C T CCPD C02C30 210 820 930 250 870 190

22

90

3.5

5.5 C35T30 2738 323

34 265 790 17

215

35

4 4066 D U CCPD C02D40 210 820 930 250 870 190

22 113

3.5

5.5 C35U40 2738 386

34 265 820 17

287

43.5

5 5066 D U CCPD C02D50 210 820 930 250 870 190

22 129

3.5

5.5 C35U50 2738 386

34 265 880 17

303

43.5

6 6076 E V CCG C03E60 255 1100 1240 300 1160 220

34 270

4

6

C40V60 2980 443

43 156 880 20

567

64

7 7076 E V CCG C03E70 255 1100 1240 300 1160 220

34 300

4

6

C40V70 2980 443

43 156 940 20

597

64

1000

2 2066 D U CCGD C02D20 210 820 930 250 870 190

22

93

3.5

5.5 C35U20 2738 386

60 306 790 17

267

43.5

3 3066 D U CCGD C02D30 210 820 930 250 870 190

22 163

3.5

5.5 C35U30 2738 386

60 306 850 17

337

43.5

4 4076 E V CCGD C03E40 255 1100 1240 300 1160 220

34 212

4

6

C40V40 2980 443

60 306 910 20

509

64

5 5076 E V CCGD C03E50 255 1100 1240 300 1160 220

34 241

4

6

C40V50 2980 443

60 306 970 20

538

64

6 6076 F Z CCGD C03F60 255 1100 1240 300 1160 220

34 298

4

6

C40Z60 2980 513

60 306 1100 20

680

75.2

7 7076 F Z CCGD C03F70 255 1100 1240 300 1160 220

34 331

4

6

C40Z70 2980 513

60 306 1160 20

713

75.2

GBP/GBA SERIES JIB CRANES – C VERSION –

CHANNEL PROFILE VERSION

Heights L*, M* and N* for wall-mounted jib cranes. See corresponding heights relative to column-mounted jib cranes.

Wall-mounted jib crane - Rotation 270°

Column-mounted jib crane - Rotation 300°