HEALTH & SAFETY

1-16

L025317 Issue 5 July 2014

Laser

D120i

10W laser head,

i-Tech

scan head, 10.6μm, fan cooled

D120i IP

10W laser head,

i-Tech

scan head, 10.6μm, IP65, compressed air cooled

D120i BLUE

10W Laser head,

i-Tech

scan head, 9.3μm, fan cooled

D120i BLUE IP

10W Laser head,

i-Tech

scan head, 9.3μm, IP65, compressed air cooled

D320i

30W laser head,

i-Tech

scan head, 10.6μm, fan cooled

D320i IP

30W laser head,

i-Tech

scan head, 10.6μm, IP65, compressed air cooled

D320i BLUE

30W Laser head,

i-Tech

scan head, 9.3μm, fan cooled

D320i BLUE IP

30W Laser head,

i-Tech

scan head

9.3μm, IP65, compressed air cooled

D320i RED

30W Laser head,

i-Tech

scan head, 10.2μm, fan cooled

D320i RED IP

30W Laser head,

i-Tech

scan head, 10.2μm, compressed air cooled

D520i

55W laser head,

i-Tech

scan head, 10.6μm, fan cooled

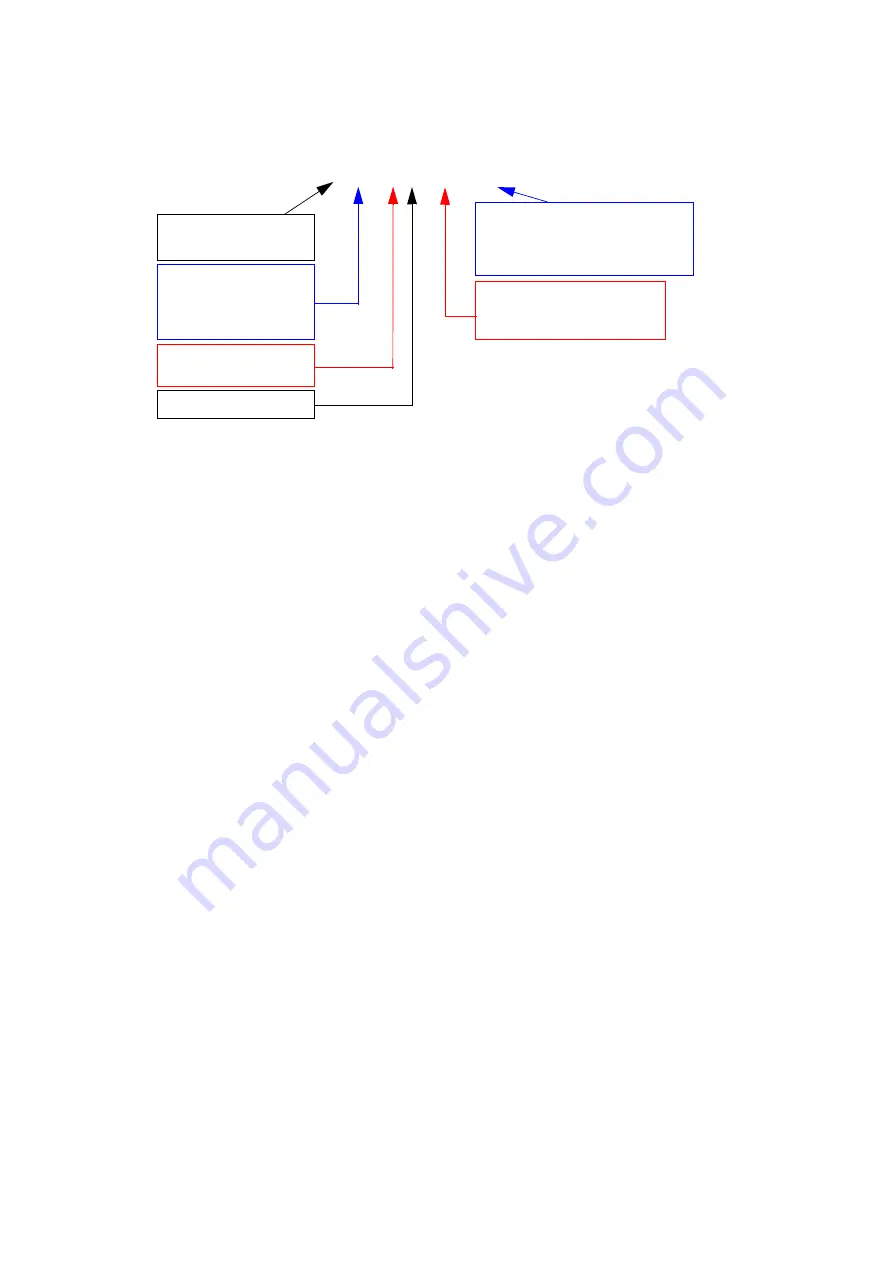

D

X

YY

i

YYYY

XX

D

-Series

Product Family

1 =

10 Watt laser

3

= 30 Watt laser

6

= 60 Watt laser

20

=

second

controller generation

i = i-Tech

=

air cooled laser

IP

= compressed air cooled laser

(10 W and 30 W)

IP

= water cooled laser (60 W)

= wavelength 10.6 μm

BLUE

= wavelength 9.3 μm

RED

= wavelength 10.2 μm

Summary of Contents for D120i Blue IP

Page 1: ...Domino D Series Product Manual ...

Page 3: ...L025317 Issue 5 July 2014 3 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 6: ... 6 L025317 Issue 5 July 2014 ...

Page 8: ... 8 L025317 Issue 5 July 2014 ...

Page 9: ...L025317 Issue 5 July 2014 9 ...

Page 20: ... 20 L025317 Issue 5 July 2014 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 22: ...HEALTH SAFETY 1 2 L025317 Issue 5 July 2014 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 42: ...HEALTH SAFETY 1 22 L025317 Issue 5 July 2014 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 58: ...INSTALLATION INSTRUCTIONS 2 16 L025317 Issue 5 July 2014 X2 Connector Schematic Beacons ...

Page 70: ...INSTALLATION INSTRUCTIONS 2 28 L025317 Issue 5 July 2014 X23 Connector Schematic RS232 COM1 ...

Page 104: ...INSTALLATION INSTRUCTIONS 2 62 L025317 Issue 5 July 2014 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 109: ...OPERATION L025317 Issue 5 July 2014 3 5 ...

Page 110: ...OPERATION 3 6 L025317 Issue 5 July 2014 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 164: ...OPERATION 3 60 L025317 Issue 5 July 2014 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 166: ...TECHNICAL REFERENCE 4 2 L025317 Issue 5July 2014 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 188: ...TECHNICAL REFERENCE 4 24 L025317 Issue 5July 2014 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 218: ...APPENDIX FONTS A 2 L025317 Issue 5 July 2014 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 220: ...APPENDIX BARCODES B 2 L025317 Issue 5 July 2014 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 224: ...APPENDIX BARCODES B 6 L025317 Issue 5 July 2014 THIS PAGE INTENTIONALLY LEFT BLANK ...