____________________________________________________________________________________

DESMI Pumping Technology A/S

16

Tagholm 1

9400 Nørresundby

–

Denmark

Tel: +45 96 32 81 11 Fax: +45 98 17 54 99

E-mail:

If the pump liquid temperature is above 80

℃

, high-temperature grease is recommended, e.g. SKF

LGHP2.

DESMI use SKF LGHP2 as standard.

Vibration levels higher than 7 mm/s at pump bearing are considered damaging and will normally result in

significantly shorter grease and/or bearing life

– especially for pumps not running. Hence shorter re-

greasing intervals might be required for pumps installed where external excited vibration levels can be

higher than 7 mm/s.

Note that relubrication can cause a (usually temporary) bearing temperature rise of up to approx. 20 ° C -

especially by mixing different types of grease and / or by overlubricating the bearing.

Grease used for relubrication must be compatible with the grease in the bearing unit.

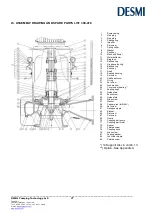

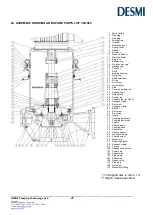

12. REPAIRS

12.1 ORDERING SPARE PARTS

When ordering spare parts please always state pump type, serial No. (appears on the name plate of the

pump), position No. on the assembly drawing and designation on the spare parts list.

13. OPERATING DATA

The following working pressures (pressure in piping incl. the pressure increase caused by the pump) and

number of revolutions are allowed in standard pumps.

Pump size

Max.

working

pressure

[bar]

Bronze /

Cast iron

Max.

working

pressure

[bar]

SG-iron

Max. RPM

Light/heavy

bearing

housing

Pump size

Max.

working

pressure

[bar]

Bronze /

Cast iron

Max.

working

pressure

[bar]

SG-iron

Max. RPM

65-215

16

25

1800/3600

150-415

9 / 13

25

1800

65-265

14.5

25

1800/3600

150-465

9

-

1800

80-330

15

25

3600/---

150-265

10

25

1800

80-215

13

25

1800/3600

200-525

14

25

1800

80-265

14.5

25

1800/3600

200-330

7 / 13

25

1800

100-330

11 / 14

25

3000/3600

200-415

9 / 13

25

1800

100-415

10 / 12.5

25

1800/---

200-265

10 / 12.5

25

1800

100-465

8

25

1800

250-330

7 / 12

25

1800

100-215

12.5

25

1800/3600

250-415

9 / 12

25

1800

100-265

14.5

25

1800/3600

250-525

14

25

1800

125-330

11 / 12

25

1800

300-415

9 / 12

25

1800

125-415

9 / 13

25

1800

300-418

6/16

25

1600

125-215

8

25

1800

300-525

14

25

1800

125-265

7

25

1800

350-525

-/16

25

1600

150-330

7 / 13

25

1800

Notice:

Some pump combinations allow higher speeds than stated in the table

–see actual pump name plate.