____________________________________________________________________________________

DESMI Pumping Technology A/S

14

Tagholm 1

9400 Nørresundby

–

Denmark

Tel: +45 96 32 81 11 Fax: +45 98 17 54 99

E-mail:

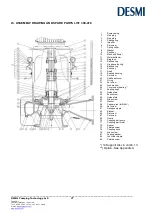

Only the upper bearing (15) is lubricated for life, whereas the lower is to be relubricated through the

lubricator nipple (84) in accordance with the table below. The replacement of bearings to be made under

the same conditions and according to the same procedure as for combination 13, however, the RS -

sealing is not to be considered.

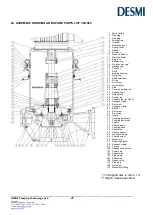

ø330/415/465/525

The bearings are dimensioned for a nominal (i.e. only obtainable for ideal greasing and operating

conditions) life of 100,000 working hours and are to be relubricated according to the below table.

Light bearing housing (combination 13):

The bearings are relubricated through the lubricator nipples (84) at top and bottom of the bearing housing

(18). In connection with replacement, the bearings are to be mounted with the RS - sealing facing

downwards, fill the bearing itself with grease and place a grease bead on the bearing towards the shaft in

a quantity corresponding to the table below.

Heavy bearing housing (combination 14):

Both bearings are relubricated through lubricator nipples (84) at top and bottom of the bearing housing

(18). See instructions for ø215/265. The top bearing (15) is to be mounted with the RS - sealing facing

downwards, fill the bearing itself with grease and place a grease bead on the bearing towards the shaft in

a quantity corresponding to the table below.