____________________________________________________________________________________

DESMI Pumping Technology A/S

12

Tagholm 1

9400 Nørresundby

–

Denmark

Tel: +45 96 32 81 11 Fax: +45 98 17 54 99

E-mail:

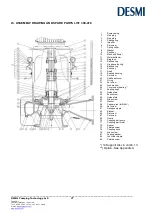

11. INSPECTION AND MAINTENANCE

Inspect the shaft seal for leaks at regular intervals.

- Before inspection of a pump without guard check that the pump cannot be started unintentionally.

- The system is to be without pressure and drained of liquid.

- The repairman must be familiar with the type of liquid which has been pumped as well as the

safety measures he is to take when handling the liquid.

The drain hole at the mechanical shaft seal must be inspected regularly (see drawing example below).

Clean the drain hole as needed. If the drain hole clogs up, leaking liquid and/or vapors from the shaft

seal can be forced up into the bearing unit, which can result in a much shorter bearing life than normal.

DRAIN HOLE FOR SHAFT SEAL