Summary of Contents for MERMAID E1100-I

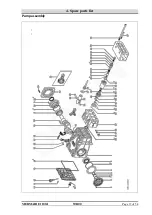

Page 38: ...4 Spare parts list MERMAID E1100 I STD00 Page 37 of 54 Pump assembly ...

Page 46: ...4 Spare parts list MERMAID E1100 I STD00 Page 45 of 54 ...

Page 47: ...4 Spare parts list MERMAID E1100 I STD00 Page 46 of 54 ...

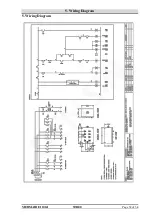

Page 53: ...5 Wiring Diagram MERMAID E1100 I STD00 Page 52 of 54 5 Wiring Diagram ...